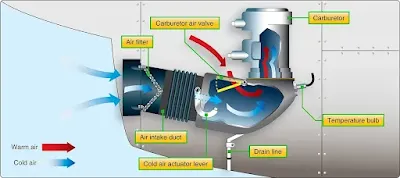

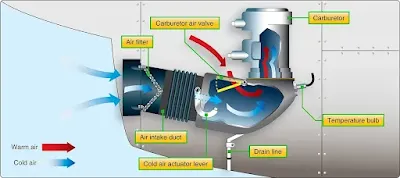

The basic induction system of an aircraft reciprocating engine consists of an air scoop used to collect the inlet air and ducting that transfers the air to the inlet filter. The air filter is generally housed in the carburetor heat box or other housing close by that is attached to the carburetor or fuel injection controller. The engine used in light aircraft is usually equipped with either a carburetor or a fuel-injection system. After air passes through the fuel metering device, an intake manifold with long curved pipes or passages is used to send the fuel/air mixture to the cylinders. An induction air scoop is shown in Figure 1.

|

| Figure 1. Inlet scoop in engine cowling |

The air scoop is located on the engine cowling to allow maximum airflow into the engine’s induction system. The air filter, shown in Figure 2, prevents dirt and other foreign matter from entering the engine. Filtered air enters the fuel metering device (carburetor/fuel injector) where the throttle plate controls the amount of air flowing to the engine. The air coming out of the throttle is referred to as manifold pressure. This pressure is measured in inches of mercury ("Hg) and controls engine power output.

|

| Figure 2. Nonsupercharged induction system using a carburetor |

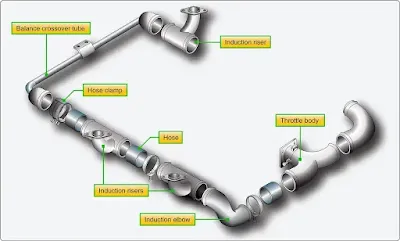

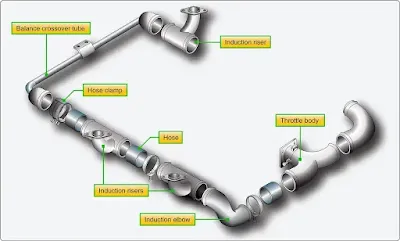

Induction systems can consist of several different arrangements. Two that are used are the updraft and downdraft induction systems. An updraft induction system consists of two runners and a balance tube with intake pipes for each cylinder to deliver induction air to each cylinder’s intake port. [Figure 3] The balance tube is used to reduce pressure imbalances between the two side induction runners. With carbureted engines, it is important to maintain a constant and even pressure in the induction system so that each cylinder receives equal amounts of fuel. On fuel-injected engines, the fuel is injected at the intake port just before the intake valve. It is important with this system to keep the pressure consistent at each intake port.

|

| Figure 3. Updraft induction system |

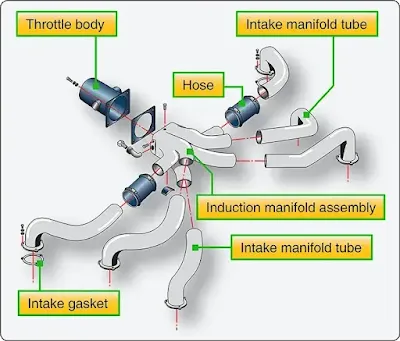

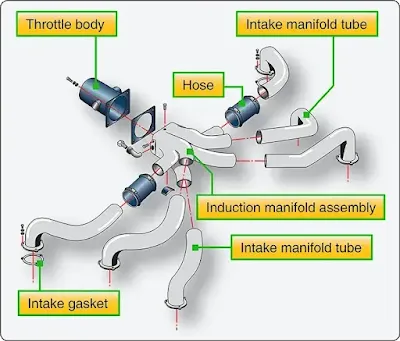

A downdraft balanced induction system provides optimum airflow to each of the individual cylinders throughout a wide operational range. [Figure 4] Better matched fuel-to-air ratios provide a much smoother and more efficient engine operation. Air from the induction manifold flows into the intake ports where it is mixed with fuel from the fuel nozzles and then enters the cylinders as a combustible mixture as the intake valve opens.

|

| Figure 4. Downdraft balanced induction system |