Combustion Process

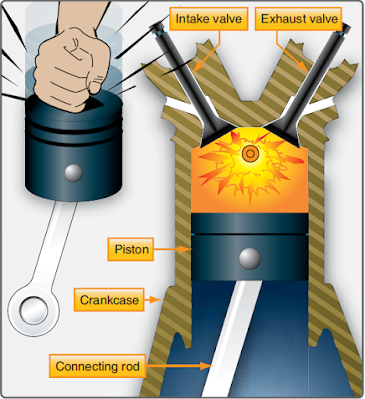

Normal combustion occurs when the fuel/air mixture ignites in the cylinder and burns progressively at a fairly uniform rate across the combustion chamber. When ignition is properly timed, maximum pressure is built up just after the piston has passed top dead center at the end of the compression stroke.The flame fronts start at each spark plug and burn in more or less wavelike forms. [Figure 1]

|

| Figure 1. Normal combustion within a cylinder |

The velocity of the flame travel is influenced by the type of fuel, the ratio of the fuel/air mixture, and the pressure and temperature of the fuel mixture. With normal combustion, the flame travel is about 100 feet/second. The temperature and pressure within the cylinder rises at a normal rate as the fuel/air mixture burns.

Detonation

There is a limit, however, to the amount of compression and the degree of temperature rise that can be tolerated within an engine cylinder and still permit normal combustion. All fuels have critical limits of temperature and compression. Beyond this limit, they ignite spontaneously and burn with explosive violence. This instantaneous and explosive burning of the fuel/air mixture or, more accurately, of the latter portion of the charge is called detonation.

Detonation is the spontaneous combustion of the unburned charge ahead of the flame fronts after ignition of the charge. [Figure 2] During normal combustion, the flame fronts progress from the point of ignition across the cylinder. These flame fronts compress the gases ahead of them. At the same time, the gases are being compressed by the upward movement of the piston. If the total compression on the remaining unburned gases exceeds the critical point, detonation occurs.

The explosive burning during detonation results in an extremely rapid pressure rise. This rapid pressure rise and the high instantaneous temperature, combined with the high turbulence generated, cause a scrubbing action on the cylinder and the piston. This can burn a hole completely through the piston.

The critical point of detonation varies with the ratio of fuel to air in the mixture. Therefore, the detonation characteristic of the mixture can be controlled by varying the fuel/air ratio. At high power output, combustion pressures and temperatures are higher than they are at low or medium power. Therefore, at high power, the fuel/air ratio is made richer than is needed for good combustion at medium or low power output. This is done because, in general, a rich mixture does not detonate as readily as a lean mixture.

Unless detonation is heavy, there is no flight deck evidence of its presence. Light to medium detonation does not cause noticeable roughness, temperature increase, or loss of power. As a result, it can be present during takeoff and high-power climb without being known to the flight crew.

In fact, the effects of detonation are often not discovered until after teardown of the engine. When the engine is overhauled, however, the presence of severe detonation during its operation is indicated by dished piston heads, collapsed valve heads, broken ring lands, or eroded portions of valves, pistons, or cylinder heads.

The basic protection from detonation is provided in the design of the engine carburetor setting, which automatically supplies the rich mixtures required for detonation suppression at high power; the rating limitations, which include the maximum operating temperatures; and selection of the correct grade of fuel. The design factors, cylinder cooling, magneto timing, mixture distribution, degree of supercharging, and carburetor setting are taken care of in the design and development of the engine and its method of installation in the aircraft.

The remaining responsibility for prevention of detonation rests squarely in the hands of the ground and flight crews. They are responsible for observance of rpm and manifold pressure limits. Proper use of supercharger and fuel mixture, and maintenance of suitable cylinder head and carburetorair- temperature (CAT) must be adhered to.

Pre-Ignition

Pre-ignition, as the name implies, means that combustion takes place within the cylinder before the timed spark jumps across the spark plug terminals. This condition can often be traced to excessive carbon or other deposits that cause local hot spots. Detonation often leads to pre-ignition. However, pre-ignition may also be caused by high-power operation on excessively lean mixtures. Pre-ignition is usually indicated in the flight deck by engine roughness, backfiring, and by a sudden increase in cylinder head temperature.

Any area within the combustion chamber that becomes incandescent serves as an igniter in advance of normal timed ignition and causes combustion earlier than desired. Preignition may be caused by an area roughened and heated by detonation erosion. A cracked valve or piston, or a broken spark plug insulator, may furnish a hot point, that serves as a glow plug.

The hot spot can be caused by deposits on the chamber surfaces resulting from the use of leaded fuels. Normal carbon deposits can also cause pre-ignition. Specifically, preignition is a condition similar to early timing of the spark. The charge in the cylinder is ignited before the required time for normal engine firing. However, do not confuse pre-ignition with the spark that occurs too early in the cycle. Pre-ignition is caused by a hot spot in the combustion chamber, not by incorrect ignition timing. The hot spot may be due to either an overheated cylinder or a defect within the cylinder.

The most obvious method of correcting pre-ignition is to reduce the cylinder temperature. The immediate step is to retard the throttle. This reduces the amount of fuel charge and the amount of heat generated. If a supercharger is in use, reduce manifold pressure as much as possible to reduce the charge temperature. Following this, the mixture should be enriched, if possible, to lower combustion temperature. If the engine is at high power when pre-ignition occurs, retarding the throttle for a few seconds may provide enough cooling to chip off some of the lead, or other deposit, within the combustion chamber. These chipped-off particles pass out through the exhaust.

Backfiring

When a fuel/air mixture does not contain enough fuel to consume all the oxygen, it is called a lean mixture. Conversely, a charge that contains more fuel than required is called a rich mixture. An extremely lean mixture either does not burn at all or burns so slowly that combustion is not complete at the end of the exhaust stroke. The flame lingers in the cylinder and then ignites the contents in the intake manifold or the induction system when the intake valve opens. This causes an explosion known as backfiring, which can damage the carburetor and other parts of the induction system.

Incorrect ignition timing, or faulty ignition wires, can cause the cylinder to fire at the wrong time, allowing the cylinder to fire when the intake valve is open, which can cause backfiring. A point worth stressing is that backfiring rarely involves the whole engine. Therefore, it is seldom the fault of the carburetor. In practically all cases, backfiring is limited to one or two cylinders. Usually, it is the result of faulty valve clearance setting, defective fuel injector nozzles, or other conditions that cause these cylinders to operate leaner than the engine as a whole. There can be no permanent cure until these defects are discovered and corrected. Because these backfiring cylinders fire intermittently and, therefore, run cool, they can be detected by the cold cylinder check.

In some instances, an engine backfires in the idle range but operates satisfactorily at medium and high power settings. The most likely cause, in this case, is an excessively lean idle mixture. Proper adjustment of the idle fuel/air mixture usually corrects this difficulty.

Afterfiring

Afterfiring, sometimes called afterburning, often results when the fuel/air mixture is too rich. Overly rich mixtures are also slow burning, therefore, charges of unburned fuel are present in the exhausted gases. Air from outside the exhaust stacks mixes with this unburned fuel that ignites. This causes an explosion in the exhaust system. Afterfiring is perhaps more common where long exhaust ducting retains greater amounts of unburned charges. As in the case of backfiring, the correction for afterfiring is the proper adjustment of the fuel/air mixture.

Afterfiring can also be caused by cylinders that are not firing because of faulty spark plugs, defective fuel-injection nozzles. or incorrect valve clearance. The unburned mixture from these dead cylinders passes into the exhaust system, where it ignites and burns. Unfortunately, the resultant torching or afterburning can easily be mistaken for evidence of a rich carburetor. Cylinders that are firing intermittently can cause a similar effect. Again, the malfunction can be remedied only by discovering the real cause and correcting the defect. Dead or intermittent cylinders can be located by the cold cylinder check.