The formation of ice on the propeller leading edges, cuffs, and spinner reduces the efficiency of the powerplant system. Deice systems using electrical heating elements and systems using chemical deicing fluid are used.

RELATED POSTS

Electrothermal Propeller Device System

Many propellers are deiced by an electrically heated boot on each blade. The boot, firmly cemented in place, receives current from a slip ring and brush assembly on the spinner bulkhead. The slip ring transmits current to the deice boot. The centrifugal force of the spinning propeller and air blast breaks the ice particles loose from the heated blades. [Figure 1]

|

| Figure 1. Electro thermal propeller deice system components |

On one aircraft model, the boots are heated in a preset sequence, which is an automatic function controlled by a timer. This sequence is as follows: 30 seconds for the right prop outer elements; 30 seconds for the right prop inner elements; 30 seconds for the left prop outer elements; and, 30 seconds for the left prop inner elements.

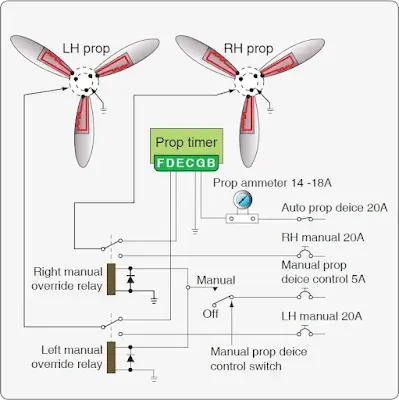

Once the system is turned on for automatic is activated, it cycles continuously. A manual bypass of the timer is incorporated. [Figure 2]

|

| Figure 2. Propeller electrical deice system schematic |

Chemical Propeller Deice

Some aircraft models, especially single-engine GA aircraft, use a chemical deicing system for the propellers. Ice usually appears on the propeller before it forms on the wing. The glycol-based fluid is metered from a tank by a small electrically driven pump through a microfilter to the slinger rings on the prop hub. The propeller system can be a stand-alone system, or it can be part of a chemical wing and stabilizer deicing system such as the TKS™ weeping system.