Fluid Line Identification

Fluid lines in aircraft are often identified by markers made up of color codes, words, and geometric symbols. These markers identify each line’s function, content, and primary hazard. Figure 1 illustrates the various color codes and symbols used to designate the type of system and its contents.

Fluid lines are marked, in most instances, with 1" tape or decals. [Figure 2A] On lines 4" in diameter (or larger), lines in oily environment, hot lines, and on some cold lines, steel tags may be used in place of tape or decals. [Figure 2B] Paint is used on lines in engine compartments where there is the possibility of tapes, decals, or tags being drawn into the engine induction system.

In addition to the above-mentioned markings, certain lines may be further identified regarding specific function within a system (e.g., drain, vent, pressure, or return). Lines conveying fuel may be marked FLAM [Figure 2]; lines containing toxic materials are marked TOXIC in place of FLAM. Lines containing physically dangerous materials, such as oxygen, nitrogen, or Freon™, may be marked PHDAN.

Aircraft and engine manufacturers are responsible for the original installation of identification markers, but the aviation mechanic is responsible for the replacement when it becomes necessary. Tapes and decals are generally placed on both ends of a line and at least once in each compartment through which lines run. In addition, identification markers are placed immediately adjacent to each valve, regulator, filter, or other accessories within a line. Where paint or tags are used, location requirements are the same as for tapes and decals.

Fluid Line End Fittings

Depending on the type and use, fittings have either pipe threads or machine threads. Pipe threads are similar to those used in ordinary plumbing and are tapered, both internal and external. External threads are referred to as male threads and internal threads are female threads.

When two fittings are joined, a male into a female, the thread taper forms a seal. Some form of pipe thread lubricant approved for particular fluid application should be used when joining pipe threads to prevent seizing and high-pressure leakage. Use care when applying thread lubricant so that the lubricant does not enter and contaminate the system. Do not use lubricants on oxygen lines. Oxygen reacts with petroleum products and can ignite (special lubricants are available or oxygen systems).

Machine threads have no sealing capability and are similar to those used on common nuts and bolts. This type of fitting is used only to draw connections together or for attachment through bulkheads. A flared tube connection, a crush washer, or a synthetic seal is used to make the connection fluid tight. Machine threads have no taper and do not form a fluid-tight seal. The size of these fittings is given in dash numbers, which equal the nominal outside diameter in sixteenths of an inch.

Universal Bulkhead Fittings

When a fluid line passes through a bulkhead, and it is desired to secure the line to the bulkhead, a bulkhead fitting should be used. The end of the fitting that passes through the bulkhead is longer than the other end(s), which allows a locknut to be installed, securing the fitting to the bulkhead.

Fittings attach one piece of tubing to another or to system units. There are four types: (1) bead and clamp, (2) flared fittings, (3) flareless fittings, and (4) permanent fittings (Permaswage™, Permalite™, and Cyrofit™). The amount of pressure that the system carries and the material used are usually the deciding factors in selecting a connector.

The beaded type of fitting, which requires a bead and a section of hose and hose clamps, is used only in low- or medium-pressure systems, such as vacuum and coolant systems. The flared, flareless, or permanent-type fittings may be used as connectors in all systems, regardless of the pressure.

AN Flared Fittings

A flared tube fitting consists of a sleeve and a nut. [Figure 3] The nut fits over the sleeve and, when tightened, draws the sleeve and tubing flare tightly against a male fitting to form a seal. Tubing used with this type of fitting must be flared before installation. The male fitting has a cone-shaped surface with the same angle as the inside of the flare. The sleeve supports the tube so that vibration does not concentrate at the edge of the flare and distributes the shearing action over a wider area for added strength.

Fitting combinations composed of different alloys should be avoided to prevent dissimilar metal corrosion. As with all fitting combinations, ease of assembly, alignment, and proper lubrication should be assured when tightening fittings during installation.

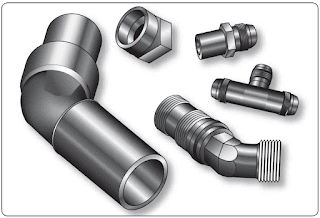

Standard AN fittings are identified by their black or blue color. All AN steel fittings are colored black, all AN aluminum fittings are colored blue, and aluminum bronze fittings are cadmium plated and natural in appearance. A sampling of AN fittings is shown in Figure 4. Figure 5 contains additional information on sizes, torques, and bend radii. AN flared fittings are different from MS flareless fittings and they are not interchangeable. AN flared fittings are easily recognized, because they have a cone at the end of the fitting while the MS flareless fitting has a straight end. [Figure 6]

MS Flareless Fittings

MS flareless fittings are designed primarily for high-pressure (3,000 psi) hydraulic systems that may be subjected to severe vibration or fluctuating pressure. [Figure 7] Using this type of fitting eliminates all tube flaring, yet provides a safe and strong, dependable tube connection. The fitting consists of three parts: a body, a sleeve, and a nut. [Figure 8] The internal design of the body causes the sleeve to cut into the outside of the tube when the body and nut are joined. The counterbore shoulder within the body is designed with a reverse angle of 15° for steel connectors and 45° for aluminum fittings. This reverse angle prevents inward collapse of the tubing when tightened and provides a partial sealing force to be exerted against the periphery of the body counterbore.

Swaged Fittings

A popular repair system for connecting and repairing hydraulic lines on transport category aircraft is the use of Permaswage™ fittings. Swaged fittings create a permanent connection that is virtually maintenance free. Swaged fittings are used to join hydraulic lines in areas where routine disconnections are not required and are often used with titanium and corrosion-resistant steel tubing. The fittings are installed with portable hydraulically-powered tooling, which is compact enough to be used in tight spaces. [Figure 9] If the fittings need to be disconnected, cut the tubing with a tube cutter. Special installation tooling is available in portable kits. Always use the manufacturer’s instructions to install swaged fittings. Typical Permaswage™ fittings are shown in Figure 10.

One of the latest developments is the Permalite™ fitting. Permalite™ is a tube fitting that is mechanically attached to the tube by axial swaging. Permalite™ works by deforming the fitting into the tube being joined by moving a ring, a component of the Permalite™ fitting, axially along the fitting length using a Permaswage Axial swage tool. Typical Permalite™ fittings are shown in Figure 11.

Cryofit Fittings

Many transport category aircraft use Cryofit fittings to join hydraulic lines in areas where routine disconnections are not required. Cryofit fittings are standard fittings with a cryogenic sleeve. The sleeve is made of a shape memory alloy, Tinel™. The sleeve is manufactured 3 percent smaller, frozen in liquid nitrogen, and expanded to 5 percent larger than the line. During installation, the fitting is removed from the liquid nitrogen and inserted onto the tube. During a 10 to 15 second warming up period, the fitting contracts to its original size (3 percent smaller), biting down on the tube, forming a permanent seal. Cryofit fittings can only be removed by cutting the tube at the sleeve, though this leaves enough room to replace it with a swaged fitting without replacing the hydraulic line. It is frequently used with titanium tubing. The shape memory technology is also used for end fittings, flared fittings, and flareless fittings. [Figure 12]

Rigid Tubing Installation and Inspection

Before installing a line assembly in an aircraft, inspect the line carefully. Remove dents and scratches, and be sure all nuts and sleeves are snugly mated and securely fitted by proper flaring of the tubing. The line assembly should be clean and free of all foreign matter.

Connection and Torque

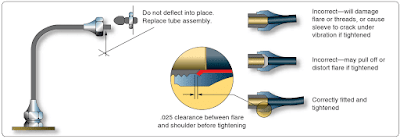

Never apply compound to the faces of the fitting or the flare, as it destroys the metal-to-metal contact between the fitting and flare, a contact which is necessary to produce the seal. Be sure that the line assembly is properly aligned before tightening the fittings. Do not pull the installation into place with torque on the nut. Correct and incorrect methods of installing flared tube assemblies are illustrated in Figure 13. Proper torque values are given in Figure 7. Remember that these torque values are for flared-type fittings only. Always tighten fittings to the correct torque value when installing a tube assembly. Overtightening a fitting may badly damage or completely cut off the tube flare, or it may ruin the sleeve or fitting nut. Failure to tighten sufficiently also may be serious, as this condition may allow the line to blow out of the assembly or to leak under system pressure. The use of torque wrenches and the prescribed torque values prevents overtightening or undertightening. If a tube fitting assembly is tightened properly, it may be removed and retightened many times before reflaring is necessary.

Flareless Tube Installation

Tighten the nut by hand until an increase in resistance to turning is encountered. Should it be impossible to run the nut down with the fingers, use a wrench, but be alert for the first signs of bottoming. It is important that the final tightening commence at the point where the nut just begins to bottom. Use a wrench and turn the nut one-sixth turn (one flat on a hex nut). Use a wrench on the connector to prevent it from turning while tightening the nut. After the tube assembly is installed, the system should be pressure tested. It is permissible to tighten the nut an additional one-sixth turn (making a total of one-third turn), should a connection leak. If leakage still occurs after tightening the nut a total of one-third turn, remove the assembly and inspect the components for scores, cracks, presence of foreign material, or damage from overtightening. Several aircraft manufacturers include torque values in their maintenance manuals to tighten the flareless fittings.

The following notes, cautions, and faults apply to the installation of rigid tubing.

Note: Overtightening a flareless tube nut drives the cutting edge of the sleeve deeply into the tube, causing the tube to be weakened to the point where normal in-flight vibration could cause the tube to shear. After inspection (if no discrepancies are found), reassemble the connections and repeat the pressure test procedures.

Caution: Never tighten the nut beyond one-third turn (two flats on the hex nut); this is the maximum the fitting may be tightened without the possibility of permanently damaging the sleeve and nut.

Common faults: Flare distorted into nut threads; sleeve cracked; flare cracked or split; flare out of round; inside of flare rough or scratched; and threads of nut or union dirty, damaged, or broken.

Rigid Tubing Inspection and Repair

Minor dents and scratches in tubing may be repaired. Scratches or nicks not deeper than 10 percent of the wall thickness in aluminum alloy tubing, which are not in the heel of a bend, may be repaired by burnishing with hand tools. The damage limits for hard, thin-walled corrosion-resistant steel and titanium tubing are considerably less than for aluminum tubing and might depend on the aircraft manufacturer. Consult the aircraft maintenance manual for damage limits. Replace lines with severe die marks, seams, or splits in the tube. Any crack or deformity in a flare is unacceptable and is cause for rejection. A dent of less than 20 percent of the tube diameter is not objectionable, unless it is in the heel of a bend. To remove dents, draw a bullet of proper size through the tube by means of a length of cable, or push the bullet through a short straight tube by means of a dowel rod. In this case, a bullet is a ball bearing or slug normally made of steel or some other hard metal. In the case of soft aluminum tubing, a hard wood slug or dowel may even be used as a bullet. [Figure 14] A severely damaged line should be replaced. However, the line may be repaired by cutting out the damaged section and inserting a tube section of the same size and material. Flare both ends of the undamaged and replacement tube sections and make the connection by using standard unions, sleeves, and tube nuts. Aluminum 6061-T6, corrosion-resistant steel 304-1/8h and Titanium 3AL-2.5V tubing can be repaired by swaged fittings. If the damaged portion is short enough, omit the insert tube and repair by using one repair union. [Figure 15] When repairing a damaged line, be very careful to remove all chips and burrs. Any open line that is to be left unattended for some time should be sealed, using metal, wood, rubber, or plastic plugs or caps.

When repairing a low-pressure line using a flexible fluid connection assembly, position the hose clamps carefully to prevent overhang of the clamp bands or chafing of the tightening screws on adjacent parts. If chafing can occur, the hose clamps should be repositioned on the hose. Figure 16 illustrates the design of a flexible fluid connection assembly and gives the maximum allowable angular and dimensional offset.

When replacing rigid tubing, ensure that the layout of the new line is the same as that of the line being replaced. Remove the damaged or worn assembly, taking care not to further damage or distort it, and use it as a forming template for the new part. If the old length of tubing cannot be used as a pattern, make a wire template, bending the pattern by hand as required for the new assembly. Then bend the tubing to match the wire pattern. Never select a path that does not require bends in the tubing. A tube cannot be cut or flared accurately enough so that it can be installed without bending and still be free from mechanical strain. Bends are also necessary to permit the tubing to expand or contract under temperature changes and to absorb vibration. If the tube is small (under 1⁄4") and can be hand formed, casual bends may be made to allow for this. If the tube must be machine formed, definite bends must be made to avoid a straight assembly. Start all bends a reasonable distance from the fittings because the sleeves and nuts must be slipped back during the fabrication of flares and during inspections. In all cases, the new tube assembly should be so formed prior to installation that it is not necessary to pull or deflect the assembly into alignment by means of the coupling nuts.