Many certified engines are used with light-sport and experimental aircraft. Generally, cost is a big factor when considering this type of powerplant. The certified engines tend to be much more costly than the non-certified engines, and are not ASTM approved.

RELATED POSTS

Rotax 912/914

Figure 1 shows a typical four cylinder, four-stroke Rotax horizontally opposed engine. The opposed-type engine has two banks of cylinders directly opposite each other with a crankshaft in the center. The pistons of both cylinder banks are connected to the single crankshaft. The engine cylinder heads are both liquid cooled and air cooled; the aircooling is mostly used on the cylinder. It is generally mounted with the cylinders in a horizontal position. |

| Figure 1. Typical four cylinder, four-stroke horizontally opposed engine |

The opposed-type engine has a low weight to horsepower ratio, and its narrow silhouette makes it ideal for horizontal installation on the aircraft wings (twin-engine applications). Another advantage is its low vibration characteristics. It is an ideal replacement for the Rotax 582 two-cylinder, two-stroke engine, which powers many of the existing light aircraft, as it is the same weight as the Rotax 582. These engines are ASTM approved for installation into light-sport category aircraft, with some models being FAA certified engines.

Description of Systems

Cooling System

The cooling system of the Rotax 914, shown in Figure 2, is designed for liquid cooling of the cylinder heads and ram-air cooling of the cylinders. The cooling system of the cylinder heads is a closed circuit with an expansion tank. [Figure 3] The coolant flow is forced by a water pump driven from the camshaft, from the radiator, to the cylinder heads. From the top of the cylinder heads, the coolant passes on to the expansion tank (1). Since the standard location of the radiator (2) is below engine level, the expansion tank located on top of the engine allows for coolant expansion.The expansion tank is closed by a pressure cap (3) (with excess pressure valve and return valve). As the temperature of the coolant rises, the excess pressure valve opens and the coolant flows via a hose at atmospheric pressure to the transparent overflow bottle (4). When cooling down, the coolant is sucked back into the cooling circuit. Coolant temperatures are measured by means of temperature probes installed in the cylinder heads 2 and 3. The readings are taken on measuring the hottest point of cylinder head depending on engine installation. [Figure 2]

Fuel System

The fuel flows from the tank (1) via a coarse filter/water trap (2) to the two electric fuel pumps (3) connected in series. [Figure 4] From the pumps, fuel passes on via the fuel pressure control (4) to the two carburetors (5). Parallel to each fuel pump is a separate check valve (6) installed via the return line (7) that allows surplus fuel to flow back to the fuel tank. Inspection for possible constriction of diameter or obstruction must be accomplished to avoid overflowing of fuel from the carburetors. The return line must not have any resistance to flow. The fuel pressure control ensures that the fuel pressure is always maintained approximately 0.25 bar (3.63 pounds per square inch (psi)) above the variable boost pressure in the airbox and thus, ensures proper operation of the carburetors.Lubrication System

The Rotax 914 engine is provided with a dry, sump-forced lubrication system with a main oil pump with integrated pressure regulator and an additional suction pump. [Figure 5] The oil pumps are driven by the camshaft. The main oil pump draws oil from the oil tank (1) via the oil cooler (2) and forces it through the oil filter to the points of lubrication. It also lubricates the plain bearings of the turbocharger and the propeller governor. The surplus oil emerging from the points of lubrication accumulates on the bottom of crankcase and is forced back to the oil tank by the blow-by gases. The turbocharger is lubricated via a separate oil line (from the main oil pump). The oil emerging from the lower placed turbocharger collects in the oil sump by a separate pump and is pumped back to the oil tank via the oil line (3). The oil circuit is vented via bore (5) in the oil tank.There is an oil temperature sensor in the oil pump flange for reading of the oil inlet temperature.

Electric System

The Rotax 914 engine is equipped with a dual ignition unit that uses a breakerless, capacitor discharge design with an integrated generator. [Figure 6] The ignition unit is completely free of maintenance and needs no external power supply. Two independent charging coils (1) located on the generator stator supply one ignition circuit each. The energy is stored in capacitors of the electronic modules (2). At the moment of ignition, two each of the four external trigger coils (3) actuate the discharge of the capacitors via the primary circuit of the dual ignition coils (4). The firing order is as follows: 1-4-2-3. The fifth trigger coil (5) is used to provide the revolution counter signal.Turbocharger and Control System

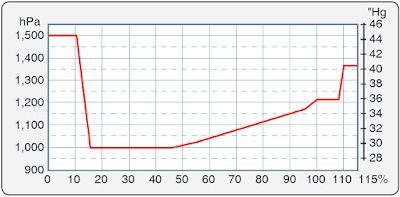

The Rotax 914 engine is equipped with an exhaust gas turbocharger making use of the energy in the exhaust gas for compression of the intake air or for providing boost pressure to the induction system. The boost pressure in the induction system (airbox) is controlled by means of an electronically controlled valve (wastegate) in the exhaust gas turbine. The wastegate regulates the speed of the turbocharger and consequently the boost pressure in the induction system. The required nominal boost pressure in the induction system is determined by the throttle position sensor mounted on the carburetor 2/4. The sensor’s transmitted position is linear from 0 to 115 percent, corresponding to a throttle position from idle to full power. [Figure 7] For correlation between throttle position and nominal boost pressure in the induction, refer to Figure 8. As shown in the diagram, with the throttle position at 108–110 percent results in a rapid rise of nominal boost pressure.To avoid unstable boost, the throttle should be moved smoothly through this area either to full power (115 percent) or at a reduced power setting to maximum continuous power. In this range (108–110 percent throttle position), small changes in throttle position have a big effect on engine performance and speed. These changes are not apparent to the pilot from the throttle lever position. The exact setting for a specific performance is virtually impossible in this range and has to be prevented, as it might cause control fluctuations or surging. Besides the throttle position, overspeeding of the engine and too high intake air temperature have an effect on the nominal boost pressure. If one of the stated factors exceeds the specified limits, the boost pressure is automatically reduced, thus protecting the engine against over boost and detonation.

The turbo control unit (TCU) is furnished with output connections for an external red boost lamp and an orange caution lamp for indications of the functioning of the TCU. When switching on the voltage supply, the two lamps are automatically subject to a function test. Both lamps illuminate for one to two seconds, then they extinguish. If they do not, a check per the engine maintenance manual is necessary. If the orange caution lamp is not illuminated, then this signals that TCU is ready for operation. If the lamp is blinking, this indicates a malfunction of the TCU or its periphery systems. Exceeding of the admissible boost pressure activates and illuminates the red boost lamp continuously. The TCU registers the time of full throttle operation (boost pressure). Full throttle operation for longer than 5 minutes, with the red boost light illuminated, makes the red boost lamp start blinking. The red boost lamp helps the pilot to avoid full power operation for longer than 5 minutes or the engine could be subject to thermal and mechanical overstress.

The turbo control unit (TCU) is furnished with output connections for an external red boost lamp and an orange caution lamp for indications of the functioning of the TCU. When switching on the voltage supply, the two lamps are automatically subject to a function test. Both lamps illuminate for one to two seconds, then they extinguish. If they do not, a check per the engine maintenance manual is necessary. If the orange caution lamp is not illuminated, then this signals that TCU is ready for operation. If the lamp is blinking, this indicates a malfunction of the TCU or its periphery systems. Exceeding of the admissible boost pressure activates and illuminates the red boost lamp continuously. The TCU registers the time of full throttle operation (boost pressure). Full throttle operation for longer than 5 minutes, with the red boost light illuminated, makes the red boost lamp start blinking. The red boost lamp helps the pilot to avoid full power operation for longer than 5 minutes or the engine could be subject to thermal and mechanical overstress.

HKS 700T Engine

The HKS 700T engine is a four-stroke, two cylinder turbocharged engine equipped with an intercooler. [Figure 9] The horizontally opposed cylinders house four valves per cylinder, with a piston displacement of 709 cc. It uses an electronic control fuel injection system. A reduction gearbox is used to drive the propeller flange at a speed reduction ratio of 2.13 to 1. The engine is rated at 77 horsepower continuous and 80 horsepower takeoff (3 minutes) at 4,900 rpm and 5,300 rpm, respectively. A total engine weight of 126 pounds provides a good power to weight ratio. The 700T has a TBO of 500 hours.Jabiru Light-Sport Engines

Jabiru engines are designed to be manufactured using the latest manufacturing techniques. [Figure 10] All Jabiru engines are manufactured, assembled, and ran on a Dynometer, then calibrated before delivery. The crankcase halves, cylinder heads, crankshaft, starter motor housings, gearbox cover (the gearbox powers the distributor rotors), together with many smaller components are machined from solid material. The sump (oil pan) is the only casting. The cylinders are machined from bar 4140 chrome molybdenum alloy steel, with the pistons running directly in the steel bores. The crankshaft is also machined from 4140 chrome molybdenum alloy steel, the journals of which are precision ground prior to being Magnaflux inspected. The camshaft is manufactured from 4140 chrome molybdenum alloy steel with nitrided journals and cams.The propeller is direct crankshaft driven and does not use a reduction gearbox. This facilitates its lightweight design and keeps maintenance costs to a minimum. The crankshaft features a removable propeller flange that enables the easy replacement of the front crankshaft seal and provides for a propeller shaft extension to be fitted, should this be required for particular applications. Cylinder heads are machined from a solid aluminum billet that is purchased directly from one company, thereby providing a substantive quality control trail to the material source. Connecting rods are machined from 4140 alloy steel and the 45 millimeters big end bearings are of the automotive slipper type. The ignition coils are sourced from outside suppliers and are modified by Jabiru for their own particular application.

An integral alternator provides AC rectification for battery charging and electrical accessories. The alternator is attached to the flywheel and is driven directly by the crankshaft. The ignition system is a transistorized electronic system; two fixed coils mounted adjacent to the flywheel are energized by magnets attached to the flywheel. The passing of the coils by the magnets creates the high voltage current, that is transmitted by high tension leads to the center post of two automotive type distributors, which are simply rotors and caps, before distribution to automotive spark plugs (two in the top of each cylinder head). The ignition system is fixed timing and, therefore, removes the need for timing adjustment. It is suppressed to prevent radio interference.

The ignition system is fully redundant, self-generating, and does not depend on battery power. The crankshaft is designed with a double bearing at the propeller flange end and a main bearing between each big end. Thrust bearings are located fore and aft of the front double bearing, allowing either tractor or pusher installation. Pistons are remachined to include a piston pin, circlip, and groove. They are all fitted with three rings, the top rings being cast iron to complement the chrome molybdenum cylinder bores. Valves are 7mm (stem diameter) and are manufactured specifically for the Jabiru engine. The valve drive train includes pushrods from the camshaft from the camshaft followers to valve rockers. The valves are Computer Numerical Control (CNC) machined from steel billet, induction hardened, polished on contact surfaces, and mounted on a shaft through Teflon coated bronze-steel bush. Valve guides are manufactured from aluminum/bronze. Replaceable valve seats are of nickel steel and are shrunk into the aluminum cylinder heads. The valve train is lubricated from the oil gallery. Engines use hydraulic lifters that automatically adjust valve clearance. An internal gear pump is driven directly by the camshaft and provides engine lubrication via an oil circuit that includes an automotive spin-on filter, oil cooler and built-in relief valve.

An integral alternator provides AC rectification for battery charging and electrical accessories. The alternator is attached to the flywheel and is driven directly by the crankshaft. The ignition system is a transistorized electronic system; two fixed coils mounted adjacent to the flywheel are energized by magnets attached to the flywheel. The passing of the coils by the magnets creates the high voltage current, that is transmitted by high tension leads to the center post of two automotive type distributors, which are simply rotors and caps, before distribution to automotive spark plugs (two in the top of each cylinder head). The ignition system is fixed timing and, therefore, removes the need for timing adjustment. It is suppressed to prevent radio interference.

The ignition system is fully redundant, self-generating, and does not depend on battery power. The crankshaft is designed with a double bearing at the propeller flange end and a main bearing between each big end. Thrust bearings are located fore and aft of the front double bearing, allowing either tractor or pusher installation. Pistons are remachined to include a piston pin, circlip, and groove. They are all fitted with three rings, the top rings being cast iron to complement the chrome molybdenum cylinder bores. Valves are 7mm (stem diameter) and are manufactured specifically for the Jabiru engine. The valve drive train includes pushrods from the camshaft from the camshaft followers to valve rockers. The valves are Computer Numerical Control (CNC) machined from steel billet, induction hardened, polished on contact surfaces, and mounted on a shaft through Teflon coated bronze-steel bush. Valve guides are manufactured from aluminum/bronze. Replaceable valve seats are of nickel steel and are shrunk into the aluminum cylinder heads. The valve train is lubricated from the oil gallery. Engines use hydraulic lifters that automatically adjust valve clearance. An internal gear pump is driven directly by the camshaft and provides engine lubrication via an oil circuit that includes an automotive spin-on filter, oil cooler and built-in relief valve.

The standard engines are supplied with two ram-air cooling ducts, that have been developed by Jabiru to facilitate the cooling of the engine by directing air from the propeller to the critical areas of the engine, particularly the cylinder heads and barrels. The use of these ducts remove the need to design and manufacture baffles and the establishment of a plenum chamber, which is the traditional method of cooling air-cooled, aircraft engines. The fact that these baffles and plenum chamber are not required also ensures a cleaner engine installation, which in turn facilitates maintenance and inspection of the engine and engine components.

The engine is fitted with a 1.5 kilowatt starter motor that is also manufactured by Jabiru and provides very effective starting. The engine has very low vibration level; however, it is also supported by four large rubber shock mounts attached to the engine mounts at the rear of the engine. The fuel induction system uses a pressure compensating carburetor. Following the carburetor, the fuel/air mixture is drawn through a swept plenum chamber bolted to the sump casting, in which the mixture is warmed prior to entering short induction tubes attached to the cylinder heads.

An effective stainless steel exhaust and muffler system is fitted as standard equipment ensuring very quiet operations. For owners wanting to fit vacuum instruments to their aircraft, the Jabiru engines are designed with a vacuum pump drive direct mounted through a coupling on the rear of the crankshaft.

The engine is fitted with a 1.5 kilowatt starter motor that is also manufactured by Jabiru and provides very effective starting. The engine has very low vibration level; however, it is also supported by four large rubber shock mounts attached to the engine mounts at the rear of the engine. The fuel induction system uses a pressure compensating carburetor. Following the carburetor, the fuel/air mixture is drawn through a swept plenum chamber bolted to the sump casting, in which the mixture is warmed prior to entering short induction tubes attached to the cylinder heads.

An effective stainless steel exhaust and muffler system is fitted as standard equipment ensuring very quiet operations. For owners wanting to fit vacuum instruments to their aircraft, the Jabiru engines are designed with a vacuum pump drive direct mounted through a coupling on the rear of the crankshaft.

Jabiru 2200 Aircraft Engine

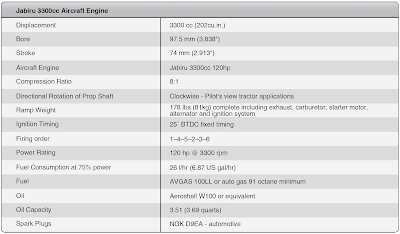

The Jabiru 2200cc aircraft engine is a four-cylinder, four-stroke horizontally opposed air cooled engine. At 132 pounds (60kgs) installed weight, it is one of the lightest four-cylinder, four-stroke aircraft engines. Small overall dimensions give it a small frontal area width (23.46 in, 596mm) that makes it a good engine for tractor applications. The Jabiru engine is designed for either tractor or pusher installation. The Jabiru engine specifications are listed in Figure 11.The Jabiru 3300 (120 hp) engine features [Figure 12]:

- 4-stroke

- 3300cc engine (200 cubic inches)

- 6-cylinder horizontally opposed

- 1 central camshaft

- Fully machined aluminum alloy crankcase

- Overhead valves (OHV) - push rod operated

- Ram-air cooled

- Wet sump lubrication - 4 liter capacity

- Direct propeller drive

- Dual transistorized magneto ignition

- Integrated AC generator

- Electric starter

- Mechanical fuel pump

- Naturally aspirated - 1 pressure compensation carburetor

Aeromax Aviation 100 (IFB) Aircraft Engine

Aeromax Aviation produces a version of a 100 hp engine called the Integral Front Bearing. The engine features a special made integral front bearing. [Figure 13] The engine uses an integral permanent magnet 35 amp alternator, lightweight starter, and dual ignition. The compact alternator and starter allow for a streamlined and aerodynamic cowl which improves the fuel efficiency of an experimental aircraft. The Aeromax aircraft engine is an opposed six-cylinder, air-cooled, and direct drive. Being a six-cylinder engine, it has smooth operation. The Aeromax engines are known for their heat dissipation qualities, provided the proper amount of cooling air is provided.It features a crank extension supported by a massive integral front bearing (IFB) and bearing housing. These engines start out as a GM Corvair automobile core engine. These basic core engines are disassembled and each component that is reused is refurbished and remanufactured. The crankshaft in the Areomax 100 IFB aircraft engine is thoroughly inspected, including a magnaflux inspection. After ensuring the crank is free of any defects, it is extended by mounting the crank extension hub on its front. Then, the crank is ground true, with all five bearings’ surfaces (four original and the new extended crank’s front bearing), being true to each other and perpendicular to the crank’s prop flange. [Figure 14]

All radiuses are smooth with no sharp corners where stress could concentrate. Every crankshaft is nitrated, which is a heat/chemical process that hardens the crank surfaces. The crank reinforcement coupled with the IFB is required to counter the additional dynamic and bending loads introduced on the crank in an aircraft application. The engine case is totally refurbished and checked for wear. Any studs or bolts that show wear are replaced. The engine heads are machined to proper specifications and all new valves, guides, and valve train components are installed. A three-angle valve grind and lapping ensure a good valve seal.

Once the engine is assembled, it is installed on a test stand, pre-lubricated, and inspected. The engine is, then, run several times for a total of two hours. The engine is carefully inspected after each run to ensure it is in excellent operating condition. At the end of test running the engine, the oil filter is removed and cut for inspection. Its internal condition is recorded. This process is documented and kept on file for each individual engine. Once the engine’s proper performance is assured, it is removed and packaged in a custom built crate for shipping. Each engine is shipped with its engine service and operations manual. This manual contains information pertaining to installation, break–in, testing, tune-up, troubleshooting, repair, and inspection procedures. The specifications for the Aeromax 100 engine are outlined in Figure 15.

- Engine General Requirements

- Personnel Authorized to Perform Inspection and Maintenance on Light-sport Engines

- Types of Light-Sport and Experimental Engines

- Direct Drive VW Engines

- Maintenance Schedule Procedures and Maintenance Checklist

- Lubrication System Maintenance

- Preflight Checks, Troubleshooting, Abnormal Operation and Preservation

- Light-Sport Jabiru Engines Maintenance Practices and Engine Inspection Charts