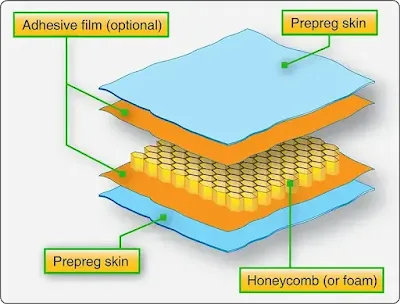

Theory A sandwich construction is a structural panel concept that consists in its simplest form of two relatively thin, parallel face sheets bonded to and separated by a relatively thick, lightweight core. The core supports the face sheets against buckling and resists out-of-plane shear loads. The core must have high shear strength and compression stiffness. Composite sandwich construction is most often fabricated using autoclave cure, press cure, or vacuum bag cure. Skin laminates may be precured and subsequently bonded to core, co-cured to core in one operation, or a combination of the two methods. Examples of honeycomb structure are: wing spoilers, fairings, ailerons, flaps, nacelles, floor boards, and rudders. [Figure 1]

Honeycomb core cells for aerospace applications are usually hexagonal. The cells are made by bonding stacked sheets at special locations. The stacked sheets are expanded to form hexagons. The direction parallel to the sheets is called ribbon direction.

|

| Figure 1. Honeycomb sandwich construction |

Properties

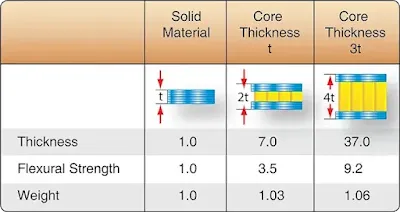

Sandwich construction has high bending stiffness at minimal weight in comparison to aluminum and composite laminate construction. Most honeycombs are anisotropic; that is, properties are directional. Figure 2 illustrates the advantages of using a honeycomb construction. Increasing the core thickness greatly increases the stiffness of the honeycomb construction, while the weight increase is minimal. Due to the high stiffness of a honeycomb construction, it is not necessary to use external stiffeners, such as stringers and frames. [Figure 2]

|

| Figure 2. Strength and stiffness of honeycomb sandwich material compared to a solid laminate |

Facing Materials

Most honeycomb structures used in aircraft construction have aluminum, fiberglass, Kevlar®, or carbon fiber face sheets. Carbon fiber face sheets cannot be used with aluminum honeycomb core material, because it causes the aluminum to corrode. Titanium and steel are used for specialty applications in high-temperature constructions. The face sheets of many components, such as spoilers and flight controls, are very thin—sometimes only 3 or 4 plies. Field reports have indicated that these face sheets do not have a good impact resistance.

Core Materials

Honeycomb

Each honeycomb material provides certain properties and has specific benefits. [Figure 3] The most common core material used for aircraft honeycomb structures is aramid paper (Nomex® or Korex®). Fiberglass is used for higher strength applications. |

| Figure 3. Honeycomb core materials |

- Kraft paper—relatively low strength, good insulating properties, is available in large quantities, and has a low cost.

- Thermoplastics—good insulating properties, good energy absorption and/or redirection, smooth cell walls, moisture and chemical resistance, are environmentally compatible, aesthetically pleasing, and have a relatively low cost.

- Aluminum—best strength-to-weight ratio and energy absorption, has good heat transfer properties, electromagnetic shielding properties, has smooth, thin cell walls, is machinable, and has a relatively low cost.

- Steel—good heat transfer properties, electromagnetic shielding properties, and heat resistant.

- Specialty metals (titanium)—relatively high strength-to-weight ratio, good heat transfer properties, chemical resistance, and heat resistant to very high temperatures.

- Aramid paper—flame resistant, fire retardant, good insulating properties, low dielectric properties, and good formability.

- Fiberglass—tailorable shear properties by layup, low dielectric properties, good insulating properties, and good formability.

- Carbon—good dimensional stability and retention, high-temperature property retention, high stiffness, very low coefficient of thermal expansion, tailorable thermal conductivity, relatively high shear modulus, and very expensive.

- Ceramics—heat resistant to very high temperatures, good insulating properties, is available in very small cell sizes, and very expensive. [Figure 3]

Honeycomb core cells for aerospace applications are usually hexagonal. The cells are made by bonding stacked sheets at special locations. The stacked sheets are expanded to form hexagons. The direction parallel to the sheets is called ribbon direction.

Bisected hexagonal core has another sheet of material cutting across each hexagon. Bisected hexagonal honeycomb is stiffer and stronger than hexagonal core. Overexpanded core is made by expanding the sheets more than is needed to make hexagons. The cells of overexpanded core are rectangular. Overexpanded core is flexible perpendicular to the ribbon direction and is used in panels with simple curves. Bell-shaped core, or flexicore, has curved cell walls, that make it flexible in all directions. Bell-shaped core is used in panels with complex curves.

Honeycomb core is available with different cell sizes. Small sizes provide better support for sandwich face sheets. Honeycomb is also available in different densities. Higher density core is stronger and stiffer than lower density core. [Figure 4]

Honeycomb core is available with different cell sizes. Small sizes provide better support for sandwich face sheets. Honeycomb is also available in different densities. Higher density core is stronger and stiffer than lower density core. [Figure 4]

|

| Figure 4. Honeycomb density |

Foam

Foam cores are used on homebuilts and lighter aircraft to give strength and shape to wing tips, flight controls, fuselage sections, wings, and wing ribs. Foam cores are not commonly used on commercial type aircraft. Foams are typically heavier than honeycomb and not as strong. A variety of foams can be used as core material including:

RELATED POSTS

- Polystyrene (better known as styrofoam)—aircraft grade styrofoam with a tightly closed cell structure and no voids between cells; high compressive strength and good resistance to water penetration; can be cut with a hot wire to make airfoil shapes.

- Phenolic—very good fire-resistant properties and can have very low density, but relatively low mechanical properties.

- Polyurethane—used for producing the fuselage, wing tips, and other curved parts of small aircraft; relatively inexpensive, fuel resistant, and compatible with most adhesives; do not use a hot wire to cut polyurethane foam; easily contoured with a large knife and sanding equipment.

- Polypropylene—used to make airfoil shapes; can be cut with a hot wire; compatible with most adhesives and epoxy resins; not for use with polyester resins, dissolves in fuels and solvents.

- Polyvinyl chloride (PVC) (Divinycell, Klegecell, and Airex)—a closed cell medium- to high-density foam with high compression strength, durability, and excellent fire resistance; can be vacuum formed to compound shapes and be bent using heat; compatible with polyester, vinyl ester, and epoxy resins.

- Polymethacrylimide (Rohacell)—a closed-cell foam used for lightweight sandwich construction; excellent mechanical properties, high-dimensional stability under heat, good solvent resistance, and outstanding creep compression resistance; more expensive than the other types of foams, but has greater mechanical properties.

Balsa Wood

Balsa is a natural wood product with elongated closed cells; it is available in a variety of grades that correlate to the structural, cosmetic, and physical characteristics. The density of balsa is less than one-half of the density of conventional wood products. However, balsa has a considerably higher density than the other types of structural cores.RELATED POSTS