14 CFR Part 43—Maintenance, Preventative Maintenance Rebuilding, and Alteration

Section 43.1—Applicability

Paragraph (a) states quite clearly that aircraft (whether U.S.- or foreign-registered operating under 14 CFR part 121 or 135) and component parts thereof must be maintained in accordance with the rules set forth in this part. Although paragraph b states quite clearly the type of aircraft that this part does not apply to, it seems to have led to considerable confusion within the aviation industry. If an aircraft is flying with a Special Airworthiness—Experimental Certificate (FAA Form 8130-7, Special Airworthiness Certificate—pink color certificate) and that is the only airworthiness certificate this aircraft has ever had, then 14 CFR part 43 does not apply.

Conversely, sometimes during maintenance (especially STC modification—the STC is addressed later in this section), it becomes necessary to temporarily place the aircraft into Special Airworthiness—Experimental. This is done to show compliance with federal regulations. These aircraft must still be maintained in accordance with 14 CFR part 43, because the aircraft had a different kind of airworthiness (in this example a Standard) prior to being issued the Special Airworthiness Certificate.

Section 43.2—Records of Overhaul and Rebuilding

These terms are not defined in 14 CFR part 1 and are given full explanation in this subpart. Each term states that it may not be used to describe work done on an aircraft, airframe, aircraft engine, propeller, appliance, or component part unless that item has been:

- Disassembled

- Cleaned

- Inspected

- Repaired, as necessary

- Reassembled

- Tested

The key difference between the two terms is in determining how the item is tested. If it is “tested in accordance with approved standards acceptable to the Administration that have been developed and documented by the manufacturer, the item is said to be overhauled.” This is basically another way of describing “service limits,” a term frequently used to describe manufacturer specified acceptable limits for used parts. A “rebuilt item, on the other hand, must be tested to the same tolerances and limits as a new item.”

Section 43.3—Persons authorized to perform maintenance, preventive maintenance, rebuilding, and alterations

There are nine different persons who may perform maintenance: (Reminder: Per 14 CFR part 1, the FAA definition of a person is “an individual, firm, partnership, corporation, association, joint-stock association, or governmental entity. It includes a trustee, receiver, assignee, or similar representative of any of them.”)

1. Certificated mechanic, per 14 CFR part 65

2. Certificated repairman, per 14 CFR part 65

3. Person working under the supervision of a certificated mechanic or repairman

4. Holder of repair station certificate

5. Holder of an air carrier certificate

6. Except for holders of a sport pilot certificate, the holder of a pilot certificate issued under part 61 may perform preventive maintenance on any aircraft owned or operated by that pilot which is not used under 14 CFR part 121, 129, or 135. The holder of a sport pilot certificate may perform preventive maintenance on an aircraft owned or operated by that pilot and issued a special airworthiness certificate in the light-sport category.

7. Pilot of a helicopter (when operated under 14 CFR part 135 and in remote areas) may perform specific preventive maintenance actions. These actions may only be accomplished under the following conditions:

- The mechanical difficulty or malfunction occurred en route to or in the remote area.

- The pilot has been satisfactorily trained and is authorized in writing by the certificate holder to perform the required maintenance.

- There is no certificated mechanic available.

- The certificate holder has procedures to evaluate the work performed when a decision for airworthiness is required. The work done is listed in paragraph (c) of Appendix A.

8. Holder of part 135 certificate may allow pilots of aircraft with nine or less passenger seats to remove and reinstall cabin seats and stretchers and cabin mounted medical oxygen bottles. These actions may only be accomplished under the following conditions:

- The pilot has been satisfactorily trained and is authorized in writing by the certificate holder to perform the required maintenance.

- The certificate holder has written procedures available to the pilot to evaluate the work performed.

9. Manufacturer may inspect and rebuild any item it has manufactured.

Section 43.5—Approval for return to service after maintenance, preventive maintenance, rebuilding, and alterations

Approving an aircraft component for return to service after maintenance, preventive maintenance, rebuilding, or alteration must be done by creating an appropriate maintenance record entry as required by either 14 CFR part 43, section 43.9 or 43.11. This may include the use of FAA Form 337, Major Repair and Alteration, if the maintenance action was a major repair or a major alteration. Whenever a maintenance action is being planned, it is critical that the technician understands exactly:

- What he/she is going to do.

- How that work is classified by the FAA.

- What type of documentation is required to support this activity.

First consider whether this a repair or an alteration. This should be a relatively simply decision since a repair basically returns the aircraft to its previous or unaltered condition (i.e., replacing magnetos, an exhaust system, tires, or brakes). Even replacing an entire engine (although it is a big job) is still a repair if it is the one properly specified for that aircraft. An alteration on the other hand, always changes or modifies the aircraft from its previous state (i.e., installing winglets, new avionics, or an engine that is not listed in the aircraft TCDS).

The second question to consider is whether or not the work that to be performed constitutes a major or a minor maintenance action. A “major” action is typically one that might appreciably affect weight, balance, structural strength, performance, powerplant operation, flight characteristics, or other qualities affecting airworthiness and that are not done according to accepted practices or cannot be done by elementary operations. This is a much more complex question, but it is extremely important as it drives the final question concerning the substantiating documentation. Please refer to 14 CFR part 1 and part 43, appendix A, for additional clarification and examples.

The third question deals with the type of documentation required to substantiate the work performed. Minor repairs and alterations need only to refer to “acceptable” data, such as manufacturers’ maintenance manuals or AC 43.13-1.

The maintenance action can simply be recorded in the maintenance record as a logbook entry. Major repairs and alterations require “approved data.” Some examples of approved data are AD notes, STCs, TCDS, DER-specific delegations, and FAA-approved manufacturer Service Bulletins (SB).

Sometimes the repair or alteration being performed does not have previously-approved data. In that case, the technician may request that the FAA accomplish a “Field Approval.” In this procedure, the technician completes the front side of Form 337 through block 6 (leaving block 3 open for later FAA approval) and then indicates in block 8 on the back what work is to be done and what the substantiating reference data is. Form 337 is then submitted to the local FAA FSDO office for review and approval by an ASI. If necessary, this ASI may seek input from other ASIs or FAA specialists to assist in the review of the data. If the data is found to comply with FAA regulations, the ASI enters one of the following statements in block 3, depending on whether the ASI has performed a review of the data only or has physically inspected the aircraft:

- “The technical data identified herein has been found to comply with applicable airworthiness requirements and is hereby approved for use only on the above described aircraft, subject to conformity inspection by a person authorized in 14 CFR part 43, section 43.7.” or

- “The alteration or repair identified herein complies with the applicable airworthiness requirements and is approved for use only on the above described aircraft, subject to conformity inspection by a person authorized in 14 CFR part 43, section 43.7.”

Section 43.7—Persons authorized to approve aircraft, airframes, aircraft engines, propellers, appliances, or component parts for return to service after maintenance, preventive maintenance, rebuilding, or alteration

There are seven different persons listed in this section who may sign RTS documentation:

- Certificated mechanic or holder of an inspection authorization (IA)

- Holder of a repair station certificate

- Manufacturer

- Holder of an air carrier certificate

- Certificated private pilot

- Repairman certificated with a maintenance rating for light sport aircraft (LSA) only

- Certificated sport pilot for preventive maintenance on an aircraft owned and or operated by him or her

Note that although a certificated repairman is authorized to work on a product undergoing maintenance, preventive maintenance, rebuilding, or alterations (refer to 14 CFR part 43, section 43.3), he or she is not authorized to approve that product for RTS. He or she must make the appropriate maintenance record entry per the requirements of 14 CFR part 43, section 43.9 or 43.11.

Section 43.9—Content, form and disposition of maintenance, preventive maintenance, rebuilding, and alteration records (except inspection performed in accordance with parts 91 and 125, and sections 135.411(a)(1) and 135.419)

The first observation is that this section specifically excludes inspection entries (those are covered in 14 CFR part 43, section 43.11). This section deals exclusively with maintenance record entries.

The next observation is that the list of maintenance actions includes “preventive maintenance.” As stated in the explanation of 14 CFR part 43, section 43.3, a certificated pilot is authorized to perform preventive maintenance on the aircraft he or she owns or operates. Therefore, remember that the pilot must make a record entry of the preventive maintenance he or she has accomplished. There are three distinct issues to be addressed in the maintenance entry and they answer the questions of “what?, when?, and who?”

• What—a description of the work performed

• When—the date the work was completed

• Who

—the name of the person who did the work if other than the person who approves the RTS

—the signature, certificate number, and type of certificate of the person who is approving the work for RTS

NOTE: Frequently, logbooks have a statement entered that ends something like this: “ … and is hereby returned to service. Joe Fixer A&P, Certificate #123456789.” As this section of the regulation currently reads, that part of the record entry is not required. Title 14 of the CFR part 43, section 43.9 clearly states that “the signature constitutes the approval for return to service only for the work performed.” Furthermore, the technician is only signing off the work he or she has done. Later, 14 CFR part 43, section 43.11 explains that an inspection write-up usually carries a broader scope of responsibility. This section is very clear that the entry completed in accordance with this section only holds the technician responsible for the service maintenance action he or she entered.

If the maintenance accomplished was a major repair or alteration, the work must be documented on FAA Form 337 and requires supporting approved data. If the maintenance action was a major repair and it was done by a certificated repair station, a signed copy of the completed customer work order accompanied by a signed maintenance release may be used in lieu of the FAA Form 337.

Section 43.10—Disposition of Life-Limited Aircraft Parts

(Note the even number again. This regulation became part of 14 CFR part 43 in 2002.)

This section presents two terms not previously defined in 14 CFR:

- Life-limited part means any part that has specified a mandatory replacement limit.

- Life status means the accumulated cycles, hours, or any other mandatory limit of a life-limited part.

This section then goes on to specify what to do with parts that are temporarily removed from and then reinstalled on a type-certificated product; what to do with parts that are removed from a type certified product and not immediately reinstalled; and how to transfer life-limited parts from one type-certificated product to another.

When a life-limited part is removed, the person removing it from the type-certificated product must control the part and ensure proper tracking of the life-limiting factor. This is to prevent the installation of the part after it has reached its life limit. There are seven possible methods the technician or repair facility may choose from to comply with this requirement.

- Recordkeeping

- Tagging

- Non-permanent marking

- Permanent marking

- Segregation

- Mutilation

- Any other method approved or accepted by the FAA

When a life-limited part is transferred, the information concerning the life status of that part must be transferred with it. Although regulations already did exist that required the tracking of life-limited parts when they were installed on an aircraft, this regulation was generated to govern the disposition of such parts when they were removed from the aircraft.

Section 43.11—Content, form, and disposition of records for inspections conducted under parts 91 and 125, and sections 135.411(a)(1) and 135.419.

This section deals exclusively with inspection record entries; however, the requirements are similar to 14 CFR part 43, section 43.9 in that information of what, when, and who is required.

- What—type of inspection, including a brief description

- When—date of the inspection and the total time in service

- Who—the signature, certificate number, and kind of certificate of the person approving or disapproving the RTS

Since this is an inspection write-up and not a maintenance entry, it is quite possible that the inspecting technician could reject or disapprove the item being inspected for the RTS. When that situation occurs, the regulation states in paragraph (b) that a list of discrepancies must be given to the owner. A reference to this list and its delivery to the aircraft owner must be reflected in the record entry. Although the regulation neither specifies how those discrepancies can be cleared, nor who may do them, any appropriately-rated repair station or certificated technician can perform the required maintenance actions. When they are completed and the proper maintenance record entries are generated in accordance with 14 CFR part 43, section 43.9, the aircraft is approved for RTS. It is neither necessary to have an additional inspection, nor is it necessary to contact the disapproving inspector.

If the aircraft is on a progressive inspection program, the inspection statement changes slightly from the statement referenced earlier by adding the reference to both a “routine inspection” and a “detailed inspection.” Refer to explanatory text of 14 CFR part 43, section 43.15 for a definition of these terms. Inspections accomplished in accordance with other inspection program requirements must identify that particular program and that part of the program the inspection completed.

Section 43.12—Maintenance Records: Falsification, Reproduction, or Alteration

The aviation community relies heavily on trust and honesty in both oral and written communication. The maintenance log entries described in 14 CFR part 43, sections 43.9 and 43.11 provide the documentation trail relied upon by aircraft owners, pilots, and technicians regarding the aircraft’s maintenance history. Falsification of these records is potentially dangerous to the personnel who rely on the accuracy of these records.

This section identifies that fraudulent entries are unacceptable. If someone commits such an act, that action is the basis for suspension or revocation of the appropriate certificate, authorization, or approval. A technician who is encouraged by his or her employer, or by anyone else, to falsify records in any way should remember this comment: “Companies come and go, but my signature lasts a lifetime. I will not use it inappropriately.”

Section 43.13—Performance Rules (General)

This section deals with the specific requirements for conducting maintenance. (NOTE: This section best reflects the relationship between the FAA’s numbering of ACs and the regulations they are related to.) Paragraph 3 on the cover page of AC 43.13-2B, Acceptable Methods, Techniques, and Practices—Aircraft Alterations, dated March 3, 2008 states:

“Title 14 of the Code of Federal Regulations (14 CFR) part 43, section 43.13(a) states that each person performing maintenance, alteration, or preventive maintenance on an aircraft, engine, propeller, or appliance must use the methods, techniques, and practices prescribed in the current manufacturer’s maintenance manual or Instructions for Continued Airworthiness prepared by its manufacturer, or other methods techniques or practices acceptable to the Administrator, except as noted in section 43.16.” [Figure 1]

|

| Figure 1. AC 43.13-2B Excerpt |

Although not all ACs are linked this directly, there is a definite relationship between ACs and companion regulations. Refer to the text on ACs for additional information.

Aircraft maintenance technicians (AMTs) are highly skilled personnel, because aviation maintenance work requires great attention to detail. The complexity of technology on today’s aircraft demands a significant level of communication to properly accomplish maintenance, preventive maintenance, rebuilding, or alteration. This communication frequently comes in written form (i.e., manufacturer’s maintenance manuals or ICA). If neither of these documents provide the guidance the technician needs to perform maintenance, either AC 43.13 (AC 43.13-1 or AC 43.13-2) contain examples of “other methods, techniques, or practices acceptable to the Administrator” that may be sufficient. However, these ACs specifically state that the information is applicable to non-pressurized areas of civil aircraft weighing 12,500 lbs gross weight or less.

In addition to the documentation, the technician must also use the proper tools, equipment, and test apparatus that ensures that the work complies with accepted industry practices. If the test equipment specified by the manufacturer is not available, equipment that is determined to be equivalent and acceptable to the Administrator may be used. The technician should be cautious, however, as “proving” the equivalence of test equipment may not be as simple as it seems.

Air carriers (commercial—“scheduled” airlines operating under 14 CFR part 121, the “commuter/on demand” aircraft operating under 14 CFR part 135, and foreign air carriers and operators of U.S.-registered aircraft under 14 CFR part 129) may use the maintenance manual required by the operations specifications to comply with the requirements of this section. The operator must provide a continuous airworthiness maintenance and inspection program acceptable to the Administrator.

Section 43.15—Additional Performance Rules for Inspections

This section presents general comments concerning the responsibility of conducting an inspection and then provides details of three separate conditions. They are rotorcraft, annual and 100-hour inspections, and progressive inspections.

- Rotorcraft—If a rotorcraft is being inspected, specific items, such as rotor transmissions and drive shafts, must be inspected.

- Annual and 100-hour inspections—When performing an annual or 100-hour inspection, a checklist must be used. This checklist may be a personal one or one from the manufacturer. Either way, it must include the scope and detail of the inspection in Appendix D. Specific engine performance is also required to be tested (or monitored) as part of RTS for an annual or 100-hour inspection. This applies whether the aircraft is reciprocating or turbine powered.

- Progressive inspection—If a progressive inspection is being conducted, it must be preceded by a complete aircraft inspection. (NOTE: A progressive inspection is the result of breaking down the large task of conducting a major inspection into smaller tasks that can be accomplished periodically without taking the aircraft out of service for an extended period of time.) Two new definitions are also presented: “routine” and “detailed.” A routine inspection is a visual examination or check of the item, but no disassembly is required. A detailed inspection is a thorough examination of the item, including disassembly. The overhaul of a component is considered to be a detailed inspection. If the aircraft is away from the station where inspections are normally conducted, an appropriately rated mechanic, a certificated repair station, or the manufacturer of the aircraft may perform inspections in accordance with the procedures and using the forms of the person who would otherwise perform the inspection.

Section 43.16—Airworthiness Limitations

The technician performing inspection or maintenance actions on an aircraft must be certain he or she has all appropriate data available. Each person performing an inspection or other maintenance specified in an Airworthiness Limitations section of a manufacturer's maintenance manual or Instructions for Continued Airworthiness shall perform the inspection or other maintenance in accordance with that section, or in accordance with operations specifications approved by the Administrator under part 121 or 135, or an inspection program approved under 14 CFR part 91, section 91.409(e). ICAs, as required by 14 CFR part 21, section 21.50, must also be consulted when available. Since 1998, the FAA has required ICAs to be generated for all major alterations that are accomplished by the field approval process. This section specifies that the technician is responsible to perform inspections or maintenance specified in an airworthiness limitation in accordance with all the preceding instructions.

Section 43.17—Maintenance, preventive maintenance, or alterations performed on U.S. aeronautical products by certain Canadian persons

This section was significantly revised in 2005, as the result of a Bilateral Aviation Safety Agreement (BASA) between the United States and Canada. This section of 14 CFR part 43 defines some terms and gives specific limitations as to what an Aircraft Maintenance Engineer (AME is the Canadian equivalent to the U.S. A&P) may do to maintain U.S.-registered aircraft located in Canada. It also provides similar limitations for an Approved Maintenance Organization. (AMO is the Canadian equivalent to the U.S.-certified repair stations.)

Appendix A—Major Alterations, Major Repairs, and Preventive Maintenance

This appendix provides a comprehensive, but not exclusive, list of subjects. For instance, paragraph (a) is titled Major Alteration, and is further subdivided as follows:

- Airframe

- Powerplant

- Propeller

- Appliance

This same subdivision is used in paragraph (b), Major Repairs. Paragraph (c), Preventive Maintenance, identifies those maintenance actions that are defined as preventive maintenance, provided the maintenance does not involve complex assembly operations. Preventive maintenance work may be accomplished by the holder of at least a private pilot certificate provided he or she is the owner or operator of that aircraft, and it is not operated under 14 CFR part 121, 129, or 135.

Appendix B—Recording of Major Repairs and Major Alterations

In most cases when a major repair or alteration is accomplished, FAA Form 337, Major Repair or Alteration, is completed at least in duplicate with the original going to the aircraft owner and a copy sent to the FAA Aircraft Registration Branch in Oklahoma City where all civil aircraft information is compiled and retained. NOTE: Historically, the second copy was sent to the local FAA FSDO within 48 hours after RTS. This copy is reviewed by an ASI and then forwarded by the FSDO to FAA records in Oklahoma City. However, in the fall of 2005, the FAA made a significant change to this submittal process and now requires the technician to submit the Form 337 directly to the Aircraft Registration Branch in Oklahoma City. Although a third copy is not required, it makes good business sense for the technician or certified repair station to keep a copy of the work that was accomplished.

However, if a certificated (part 145) repair station completes a major repair, it may provide the customer with a signed copy of the work order and a maintenance release signed by an authorized representative of the repair station, instead of the FAA Form 337. If the major repair or alteration was done by an AME or AMO, the copy normally provided to the FAA-FSDO is sent directly to the FAA Aircraft Registration Branch.

However, if extended range tanks are installed in either passenger or cargo compartments, the technician must generate a third FAA Form 337 for the modification. This copy must be placed and retained in the aircraft. (Refer to 14 CFR part 91, section 91.417(d).)

Appendix C—(Reserved)

Appendix C is reserved for future use and therefore currently contains no information.

Appendix D—Scope and Detail of Items To Be Included in Annual and 100-Hour Inspections

Some important items to consider in this appendix are:

- The list of items and areas to be inspected are exactly the same for an annual as a 100-hour inspection. The difference between the inspections is in who is authorized to perform and approve the aircraft for RTS following the inspection. Refer to 14 CFR part 65, section 65.95(a)(2) that states that an IA must perform an annual inspection.

- The aircraft and engine must be cleaned prior to conducting the inspection.

- Any miscellaneous item not covered in the detailed list provided must also be inspected for improper installation and operation.

- There are eight specific areas identified for detailed inspection. They are the fuselage hull group, cabin/ flight deck group, engine/nacelle group, landing gear group, wing/center section group, empennage assembly, propeller group, and the radio group.

Appendix E—Altimeter System Test and Inspection

This is commonly referred to as “the 411 test.” Refer to 14 CFR part 91, section 91.411 that requires that no person may operate an aircraft in controlled airspace under IFR unless the aircraft has had this test completed successfully within the preceding 24 months.) This section requires detailed testing of the static pressure system, the altimeter, and the automatic pressure altitude reporting equipment, and that the test information be recorded in the maintenance logs and on the altimeter.

Appendix F—ATC Transponder Tests and Inspections

This is commonly referred to as “the 413 test.” (Refer to 14 CFR part 91, section 91.413, which requires that no person may use a transponder unless it has had this test completed successfully within the preceding 24 months.)

This section specifies complex sets of tests, which may be accomplished either as a bench test or by using portable test equipment. Major categories of the testing required are radio reply frequency, suppression, receiver sensitivity, radio frequency peak output power, and mode S (when applicable). Upon completion of testing, proper entries must be made in the maintenance record.

14 CFR Part 91—General Operating and Flight Rules

Subpart A—General

As mentioned in the brief overview of the regulation portion in the Title 14 of the Code of Federal Regulations (14CFR), this part is actually addressing the operation of the aircraft. For example, 14 CFR part 91, section 91.7(a) states “no person may operate a civil aircraft unless it is in an airworthy condition.” We learned earlier that this term means that the aircraft conforms to its approved type design and is in condition for safe operation. When the pilot performs a preflight inspection, he or she is making a determination concerning the “condition for safe operation.” The pilot does not usually determine “conformity to type design” unless he or she performs a review of the maintenance records. However, since that is fundamental to the definition of airworthy, it is still part of their responsibility. Therefore, a professional and ethical technician wants to help the customer understand his or her responsibilities in maintaining and documenting the airworthiness of the aircraft.

Subpart E—Maintenance, Preventive Maintenance, and Alterations

Section 91.401—Applicability

Although this subpart describes in general the rules regardingmaintenance, preventive maintenance, and alteration, certainsections do not apply if the aircraft is operated in accordancewith 14 CFR part 121, 125, 129, or 135.

Section 91.403—General

The owner/operator holds the primary responsibilityfor maintaining the aircraft in airworthy condition. Thisincludes compliance with all applicable ADs and is thereason that the FAA sends new AD notes to the registered owners of the affected aircraft. All maintenance performed must be accomplished in accordance with 14 CFR part 43. Compliance with the appropriate manufacturer maintenance manuals and ICA is also required. Mandatory replacement times, inspection intervals, and related procedures as outlined in the FAA-approved operations specifications must also be complied with.

Section 91.405—Maintenance Required

The owner/operator is required to have the appropriate inspections made, and to have discrepancies repaired in accordance with part 43. He or she is also required to ensure that the appropriate entries have been made in the maintenance records. Any inoperative instruments or equipment must be properly placarded as inoperative.

Section 91.407—Operation after maintenance, preventive maintenance, or alteration

Whenever the aircraft has undergone maintenance, preventive maintenance, rebuilding or alteration, it must have been approved for RTS and a proper entry made in the maintenance records. If the maintenance that was done could have appreciably changed the flight characteristics, an appropriately rated pilot must perform an operational flight check of the aircraft and must make an entry of the flight in the maintenance records. If ground testing and inspection can show conclusively that the maintenance has not adversely affected the flight characteristics, no flight test is required.

Section 91.409—Inspections

This paragraph identifies various types of inspection applicable to the civilian aircraft fleet. Paragraph (a) defines the requirement for an annual inspection. However, there are certain exceptions to this regulation:

- An aircraft that carries a special flight permit, a current experimental certificate, or a light-sport or provisional airworthiness certificate;

- An aircraft inspected in accordance with an approved aircraft inspection program under part 125 or 135 and so identified by the registration number in the operations specifications of the certificate holder having the approved inspection program;

- An aircraft subject to the requirements of paragraph (d) or (e) of this section; or

- Turbine-powered rotorcraft when the operator elects to inspect that rotorcraft in accordance with paragraph (e) of this section.

Annual inspections are usually the inspection method associated with small “general aviation” aircraft. If this same aircraft is used for hire (including flight instruction for hire), then the aircraft must also be inspected every 100 hours of time in service. This requirement for a 100-hour inspection to be conducted on an aircraft may be exceeded by as much as 10 hours if the aircraft is en route to reach a facility that will be conducting the inspection. Any time accrued between 100 and 110 hours is subtracted from the hours remaining before the next 100-hour inspection.

Since aircraft used for hire only generate revenue when they are flying, any time that the aircraft is “down for inspection” can result in a loss of income for the owner/operator. Therefore, the FAA has made provision to minimize the impact of the 100-hour and annual inspection requirement. The owner/operator may petition the local FSDO for approval of a progressive inspection program. This program breaks the complete inspection of the aircraft into smaller, less time-consuming steps. (Refer to 14 CFR part 43, Appendix D.) This inspection may be either performed or supervised by a technician holding an IA. The program must ensure at all times that the aircraft is airworthy. The owner/operator must submit an inspection schedule with his or her application to the FAA. This schedule must identify the time intervals (hours or days) when routine and detailed inspections are to be accomplished. (Refer to 14 CFR part 43, section 43.15.) Just as with the 100-hour inspection, a 10-hour maximum extension of a specified inspection interval is allowed if the aircraft is en route. A change in the inspection interval is also allowed for changes in service experience. If the progressive inspection is discontinued, the aircraft is again subject to the traditional annual and 100-hour inspections.

Other inspection programs that may be applicable to other aircraft are a continuous airworthiness inspection program and an approved aircraft inspection program (AAIP). The former program is applicable to either a part 121 or 135 carrier, but the latter program is limited to part 135 operators only. Finally, the owner/operator may use either a current inspection program recommended by the aircraft manufacturer or one established by the owner/operator and approved by the local FSDO. Any subsequent changes to that program must also be approved by the local FSDO.

There may be an instance when the operator of an aircraft wishes to change from one type of inspection program to another. In that case, the time in service, calendar times, or cycles of operation from the current program must be carried over to the subsequent program.

Section 91.411—Altimeter System and Altitude Reporting Equipment Tests and Inspections

Commonly referred to as “the 411 test,” this section specifies the requirements for testing the static pressure system, each altimeter instrument, and each automatic pressure altitude reporting system every 24 calendar months. The static system must also be tested any time it has been “opened and closed,” except for the normal use of the system drain and alternate static system pressure valves. If the automatic pressure altitude reporting system of the air traffic control (ATC) transponder is either installed or subjected to maintenance actions, the system must also be tested per Appendix E of 14 CFR part 43.

Due to the inherent design and accuracy of this system, only the aircraft manufacturer, a properly-rated repair station, or a certificated airframe mechanic may perform these tests. The airframe technician may only perform the inspection and test of the static pressure system. Calibration and maintenance of related instruments is specifically prohibited to the technician by the language of 14 CFR part 65, section 65.81 and specifically allowed in 14 CFR part 145, section 145.59 for repair stations holding an instrument rating.

TSO’d items are considered to be “tested and inspected” as of the date they were manufactured. The maximum altitude that the system was tested is the maximum altitude that the aircraft can be flown instrument flight rules (IFR) in controlled airspace.

Section 91.413—ATC Transponder Tests and Inspections

This “413 test” is the other test required every 24 months. Whenever the ATC transponder is installed or has undergone maintenance, the complete system must be tested and inspected in accordance with Appendix E of 14 CFR part 43. The transponder itself must be tested and inspected in accordance with Appendix F of 14 CFR part 43. As with the 411 test, only certain persons are authorized to conduct the tests. They are the manufacturer of the aircraft, a properly certificated repair station, or the holder of a continuous airworthiness maintenance program under 14 CFR part 121 or 135.

Section 91.415—Changes to Aircraft Inspection Programs

If the FAA determines that the inspection program established and approved under either 14 CFR part 91, section 91.409 or 91.1109 must be revised to ensure continued safety and adequacy of the program, the owner/operator must make the necessary changes as identified by the Administrator. If the owner/operator desires to contest this request, they must petition the FAA to reconsider their request to change the program within 30 days of receiving the change request from the FAA.

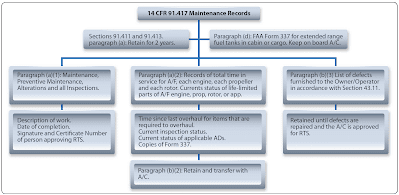

Section 91.417—Maintenance Records

The understanding and implementation of this section is fundamental to the aircraft industry, in general, and the aircraft owner/operator, in specific. A professional maintenance technician must be knowledgeable of this section and be able to help the owner/operator understand it. [Figure 2] This section identifies four types of records— two are quite specific (paragraphs a and d) and two are more general: (a)(1) and (a)(2). Paragraph (a) refers to the 411 and 413 testing that requires testing every 24 months. Therefore, records must be kept for that length of time. Paragraph (d) refers to the installation of fuel tanks in the cabin or cargo area. The FAA Form 337 authorizing this installation must be kept on board the aircraft all the time.

|

| Figure 2. Maintenance records |

NOTE: Other than this paragraph, there is no requirement that the maintenance records of the aircraft be carried on the aircraft. In fact, there are very logical reasons to not do so in most cases. The two biggest concerns are damaged or lost records. It is much safer to retain the logs in a filing system in the office. It is also a very wise idea to have the logbook copied or scanned and retained at a separate location should a catastrophic event (fire, flood, tornado, hurricane, and so forth) occur at the site the original records are retained.

Subparagraph (a)(1) then lists those records that are later defined in (b)(1) as being retained for 1 year or until the work is repeated or superseded. Subparagraph (a)(2) specifies the records that are permanent records and are identified in subparagraph (b)(2) as those that must be transferred with the aircraft. Refer to the chart for further clarification. [Figure 2]

Paragraph (c) requires that all of the maintenance records mandated by this section be made available upon request to the Administrator or any authorized representative of the NTSB. Furthermore, the owner/operator must provide the Form 337 required to be aboard the aircraft whenever additional fuel tanks are installed in either the passenger compartment or the baggage compartment, per paragraph (d), to any law enforcement officer upon request.

Section 91.419—Transfer of Maintenance Records

When an aircraft is sold, it is logical that the records are transferred with it. They may be either in plain language or coded. The purchaser may elect to permit the seller to retain the actual records; however, if that occurs the purchaser (now the current owner/operator) must still make these records available to either the FAA or the NTSB upon request.

Section 91.421—Rebuilt Engine Maintenance Records

This section presents the term “zero time.” Although not truly given as a definition, the wording of the regulation is very clear that an aircraft engine, when rebuilt by the engine manufacturer or an agency approved by the manufacturer, may be given a new maintenance record showing no previous operating history. This new record must include a signed statement with the date it was rebuilt, any changes incorporated by compliance with AD notes, and compliance with any of the manufacturer’s SB.