Oil Level Check

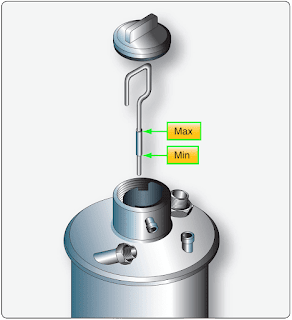

Always allow engine to cool down to ambient temperature before starting any work on the lubrication system. Severe burns and scalds may result from hot oil coming into contact with the skin. Switch off ignition and remove ignition key. To assure that the engine does not turn by the starter, disconnect the negative terminal of aircraft battery. Before checking the oil level, make sure that there is not excess residue oil in the crankcase. Prior to oil level check, turn the propeller several times by hand in the direction of engine rotation to pump all the oil from the engine to the oil tank. This process is completed when air flows back to the oil tank. This air flow can be perceived as a gurgling noise when the cap of the oil tank is removed. The oil level in the oil tank should be between the two marks (maximum/minimum) on the oil dipstick, but must never fall below the minimum mark. [Figure 1]

Replenish oil as required, but for longer flights, replenish oil to maximum mark to provide for more of an oil reserve. During standard engine operation, the oil level should be mid-way between the maximum and minimum marks a higher oil level (over servicing). Oil can escape through the venting (breather) passage.

Oil Change

It is advisable to check the oil level prior to an oil change, as it provides information about oil consumption. Run engine to warm the oil before beginning the procedure. Taking proper precautions, crank the engine by hand to transfer the oil from the crankcase. Remove the safety wire and oil drain screw (1) from the oil tank, drain the used oil, and dispose of as per environmental regulations. [Figure 2]

|

| Figure 2. Oil tank |

Remove and replace oil filter at each oil change. It is not necessary to remove oil lines and other oil connections. Draining the suction lines, oil cooler, and return line is not necessary and must be avoided, as it results in air entering the oil system. Replacement of the oil filter and the oil change should be accomplished quickly and without interruption to prevent a draining of the oil system and the hydraulic tappets. Compressed air must not be used to blow through the oil system (or oil lines, oil pump housing, oil bores in the housing). Replace the oil drain screw torque and safety wire. Only use the appropriate oil in accordance with the latest operator’s manual and service instruction. The engine must not be cranked when the oil system is open. After the oil change is accomplished, the engine should be cranked by hand in the direction of engine rotation (approximately 20 turns) to completely refill the entire oil circuit.

Cleaning the Oil Tank

Cleaning the oil is optional and requires venting of the oil system. It is only necessary to clean the oil tank and the inner parts if there is heavy oil contamination. The procedure for cleaning the oil tank is shown in Figure 2. Detach the profile clamp (2) and remove the oil tank cover (3), together with the O-ring (4) and the oil lines. Remove the inner parts of the oil tank, such as the baffle insert (5) and the partition (6). Clean oil tank (8) and inner parts (5, 6), and check for damage. Be aware that incorrect assembly of the oil tank components can cause engine faults or engine damage. Replace the drain screw with a new sealing ring (7) and tighten to 25 Newton meters (Nm) (18.5 ft/lb) and safety wire. Reassemble the oil tank by following the same steps in reverse order.

Inspecting the Magnetic Plug

Remove the magnetic plug and inspect it for accumulation of chips. [Figure 3] The magnetic plug (torx screw) is located on the crankcase between cylinder 2 and the gearbox. This inspection is important because it allows conclusions to be drawn on the internal condition of the gearbox and engine, and reveals information about possible damage. If a significant amount of metal chips are detected, the engine must be inspected, repaired, or overhauled. Steel chips in low numbers can be tolerated if the accumulation is below 3 mm (0.125 in). [Figure 3] In the case of unclear findings, flush the oil circuit and fit a new oil filter. Afterwards, conduct an engine test run and inspect the oil filter once more. If there are larger accumulations of metal chips on the magnetic plug, the engine must be repaired or overhauled in accordance with the manufacturer’s instructions for continued airworthiness. A detailed inspection of affected engine components must be performed. If the oil circuit is contaminated, replace the oil cooler and flush the oil circuit, then trace the cause and remedy the situation. If the magnetic chip is found to have no metal, then clean and reinstall. Tighten the plug to a torque of 25 Nm (18.5 ft/lb). Safety wire the plug and inspect all systems for correct function.

|

| Figure 3. Inspecting the magnetic plug |

Checking the Propeller Gearbox

The following free rotation check and friction torque check are necessary only on certified engines and on engines with the overload clutch as an optional extra. Engines without the overload clutch (slipper clutch) still incorporate the torsional shock absorption. This design is similar to the system with overload clutch, but without free rotation. For this reason, the friction torque method cannot be applied on engines without the overload clutch.

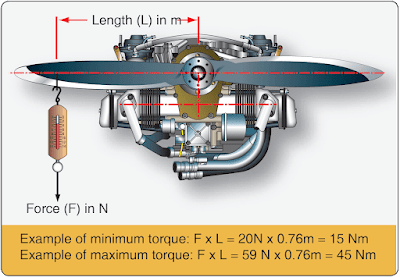

Checking the Friction Torque in Free Rotation

Fit the crankshaft with a locking pin. [Figure 4] With the crankshaft locked, the propeller can be turned by hand 15 or 30 degrees, depending on the profile of the dog gears installed. This is the maximum amount of movement allowed by the dog gears in the torsional shock absorption unit.

|

| Figure 4. Checking propeller gearbox |

WARNING: Ignition OFF and system grounded. Disconnect negative terminal of aircraft battery.

Turn the propeller by hand back and forth between ramps, taking into consideration the friction torque. No odd noises or irregular resistance must be noticeable during this movement. Attach a calibrated spring scale to the propeller at a certain distance (L) from the center of the propeller. Measure the force required to pull the propeller through the 15 or 30 degree range of free rotation. Calculate friction torque Nm by multiplying the force Newton’s (N) or pounds (lb) obtained on the spring scale by the distance the scale is attached from the center of the propeller (L). The distance measurement and torque measurement must be in the same units either standard or metric and cannot be mixed up. The friction torque must be between a minimum of 25 Nm and maximum of 60 Nm (18.5 to 44.3 ft/lb). A calculation example is as follows:

Friction Torque (FT) = Length (meters) × Newtons (torque)

FT = .5 meters × 60 Newtons

FT = 30Nm

Remove crankshaft locking pin and reinstall plug with new gasket. Reconnect negative terminal of aircraft battery. If the above mentioned friction torque is not achieved, inspect, repair, or overhaul the gearbox in accordance with the manufacturer’s instructions for continued airworthiness. Testing the propeller flange is not normal maintenance but can be carried out if defects or cracks are suspected.

Daily Maintenance Checks

The following checklist should be used for daily maintenance checks. Repair, as necessary, all discrepancies before flight.

- Verify ignition OFF.

- Drain water from fuel tank sump and/or water trap (if fitted).

- Inspect carburetor rubber socket or flange for cracks and verify secure attachment.

- Inspect carburetor float chamber for water and dirt.

- Verify security and condition of intake silencer and air filter.

- Verify security of radiator mounting. Inspect radiators for damage and leaks.

- Verify coolant level in overflow bottle and security of cap.

- Verify coolant hoses for security, and inspect for leaks and chafing.

- Inspect engine for coolant leaks (cylinder head, cylinder base, and water pump).

- Verify oil content for rotary valve gear lubrication and security of oil cap.

- Verify oil hoses for security, and inspect for leaks and chafing (rotary valve gear lubrication system and oil injection system).

- Verify ignition coils/electronic boxes for secure mounting, and check ignition leads and all electrical wiring for secure connections and chafing.

- Verify electric starter for secure mounting, and inspect cover for cracks.

- Verify engine to airframe mounting for security and inspect cracks.

- Verify fuel pump mounting for security, and inspect all fuel hose connections (filters, primer bulbs, and taps for security, leakage, chafing and kinks).

- Verify fuel pump impulse hose for secure connections, and inspect for chafing and kinks.

- Verify safety wiring of gearbox drain and level plugs.

- Inspect rubber coupling for damage and aging (C type gearbox only).

- Rotate engine by hand and listen for unusual noises (first, double verify ignition OFF).

- Check propeller shaft bearing for clearance by rocking propeller.

- Inspect throttle choke and oil pump lever cables for damage (end fittings, outer casing, and kinks).

- Engine General Requirements

- Personnel Authorized to Perform Inspection and Maintenance on Light-sport Engines

- Types of Light-Sport and Experimental Engines

- Opposed Light-Sport, Experimental, and Certified Aircraft Engines

- Direct Drive VW Engines

- Preflight Checks, Troubleshooting, Abnormal Operation and Preservation

- Maintenance Schedule Procedures and Maintenance Checklist