Paint Booth

A paint booth may be a small room in which components of an aircraft are painted, or it can be an aircraft hangar big enough to house the largest aircraft. Whichever it is, the location must be able to protect the components or aircraft from the elements. Ideally, it would have temperature and humidity controls; but, in all cases, the booth or hangar must have good lighting, proper ventilation, and be dust free.A simple paint booth can be constructed for a small aircraft by making a frame out of wood or polyvinyl chloride (PVC) pipe. It needs to be large enough to allow room to walk around and maneuver the spray gun. The top and sides can be covered with plastic sheeting stapled or taped to the frame. An exhaust fan can be added to one end with a large air-conditioning filter placed on the opposite end to filter incoming air. Lights should be large enough to be set up outside of the spray booth and shine through the sheeting or plastic windows. The ideal amount of light would be enough to produce a glare off of all the surfaces to be sprayed. This type of temporary booth can be set up in a hangar, a garage, or outside on a ramp, if the weather and temperature are favorable.

Normally, Environmental Protection Agency (EPA) regulations do not apply to a person painting one airplane. However, anyone planning to paint an aircraft should be aware that local clean air regulations may be applicable to an airplane painting project. When planning to paint an aircraft at an airport, it would be a good idea to check with the local airport authority before starting.

Air Supply

The air supply for paint spraying using a conventional siphon feed spray gun should come from an air compressor with a storage tank big enough to provide an uninterrupted supply of air with at least 90 pounds per square inch (psi) providing 10 cubic feet per minute (CFM) of air to the spray gun.The compressor needs to be equipped with a regulator, water trap, air hose, and an adequate filter system to ensure that clean, dry, oil-free air is delivered to the spray gun.

If using one of the newer high-volume low-pressure (HVLP) spray guns and using a conventional compressor, it is better to use a two stage compressor of at least a 5 horsepower (hp) that operates at 90 psi and provides 20 CFM to the gun. The key to the operation of the newer HVLP spray guns is the air volume, not the pressure.

If purchasing a new complete HVLP system, the air supply is from a turbine compressor. An HVLP turbine has a series of fans, or stages, that move a lot of air at low pressure. The more stages provide greater air output (rated in CFM) that means better atomization of the coating being sprayed. The intake air is also the cooling air for the motor. This air is filtered from dirt and dust particles prior to entering the turbine. Some turbines also have a second filter for the air supply to the spray gun. The turbine does not produce oil or water to contaminate the air supply, but the air supply from the turbine heats up, causing the paint to dry faster, so you may need an additional length of hose to reduce the air temperature at the spray gun.

Spray Equipment

Air Compressors

Piston–type compressors are available with one-stage and multiple-stage compressors, various size motors, and various size supply tanks. The main requirement for painting is to ensure the spray gun has a continuous supplied volume of air. Piston-type compressors compress air and deliver it to a storage tank. Most compressors provide over 100 psi, but only the larger ones provide the volume of air needed for an uninterrupted supply to the gun. The multistage compressor is a good choice for a shop when a large volume of air is needed for pneumatic tools. When in doubt about the size of the compressor, compare the manufacturer’s specifications and get the largest one possible. [Figure 1] |

| Figure 1. Standard air compressor |

Large Coating Containers

For large painting projects, such as spraying an entire aircraft, the quantity of mixed paint in a pressure tank provides many advantages. The setup allows a greater area to be covered without having to stop and fill the cup on a spray gun. The painter is able to keep a wet paint line, and more material is applied to the surface with less overspray. It provides the flexibility of maneuvering the spray gun in any position without the restriction and weight of an attached paint cup. Remote pressure tanks are available in sizes from 2 quarts to over 60 gallons. [Figure 2] |

| Figure 2. Pressure paint tank |

System Air Filters

The use of a piston-type air compressor for painting requires that the air supply lines include filters to remove water and oil. A typical filter assembly is shown in Figure 3. |

| Figure 3. Air line filter assembly |

Miscellaneous Painting Tools and Equipment

Some tools that are available to the painter include:- Masking paper/tape dispenser that accommodates various widths of masking paper. It includes a masking tape dispenser that applies the tape to one edge of the paper as it is rolled off to facilitate one person applying the paper and tape in a single step.

- Electronic and magnetic paint thickness gauges to measure dry paint thickness.

- Wet film gauges to measure freshly applied wet paint.

- Infrared thermometers to measure coating and substrate surfaces to verify that they fall in the recommended temperature range prior to spraying.

Spray Guns

A top quality spray gun is a key component in producing a quality finish in any coating process. It is especially important when painting an aircraft because of the large area and varied surfaces that must be sprayed.When spray painting, it is of utmost importance to follow the manufacturer’s recommendations for correct sizing of the air cap, fluid tip, and needle combinations. The right combination provides the best coverage and the highest quality finish in the shortest amount of time.

All of the following examples of the various spray guns (except the airless) are of the air atomizing type. They are the most capable of providing the highest quality finish.

Siphon-Feed Gun

The siphon-feed gun is a conventional spray gun familiar to most people, with a one quart paint cup located below the gun. Regulated air passes through the gun and draws (siphons) the paint from the supply cup. This is an external mix gun, which means the air and fluid mix outside the air cap. This gun applies virtually any type coating and provides a high quality finish. [Figure 4] |

| Figure 4. Siphon-feed spray gun |

Gravity-Feed Gun

A gravity-feed gun provides the same high-quality finish as a siphon-feed gun, but the paint supply is located in a cup on top of the gun and supplied by gravity. The operator can make fine adjustments between the atomizing pressure and fluid flow and utilize all material in the cup. This also is an external mix gun. [Figure 5] |

| Figure 5. Gravity-feed spray gun |

The HVLP production spray gun is an internal mix gun. The air and fluid is mixed inside the air cap. Because of the low pressure used in the paint application, it transfers at least 65 percent and upwards of 80 percent of the finish material to the surface. HVLP spray guns are available with a standard cup located underneath or in a gravity-feed model with the cup on top. The sample shown can be connected with hoses to a remote paint material container holding from 2 quarts to 60 gallons. [Figure 6]

|

| Figure 6. A high volume low pressure (HVLP) spray gun |

Because of more restrictive EPA regulations, and the fact that more paint is being transferred to the surface with less waste from overspray, a large segment of the paint and coating industry is switching to HVLP spray equipment.

Airless spraying does not directly use compressed air to atomize the coating material. A pump delivers paint to the spray gun under high hydraulic pressure (500 to 4,500 psi) to atomize the fluid. The fluid is then released through an orifice in the spray nozzle. This system increases transfer efficiency and production speed with less overspray than conventional air atomized spray systems. It is used for production work but does not provide the fine finish of air atomized systems. [Figure 7]

|

| Figure 7. Airless spray gun |

Fresh Air Breathing Systems

Fresh air breathing systems should be used whenever coatings are being sprayed that contain isocyanides. This includes all polyurethane coatings. The system incorporates a high-capacity electric air turbine that provides a constant source of fresh air to the mask. The use of fresh air breathing systems is also highly recommended when spraying chromate primers and chemical stripping aircraft. The system provides cool filtered breathing air with up to 200 feet of hose, which allows the air pump intake to be placed in an area of fresh air, well outside of the spraying area. [Figure 8] |

| Figure 8. Breathe-Cool II® supplied air respirator system with Tyvek® hood |

A charcoal-filtered respirator should be used for all other spraying and sanding operations to protect the lungs and respiratory tract. The respirator should be a double-cartridge, organic vapor type that provides a tight seal around the nose and mouth. The cartridges can be changed separately, and should be changed when detecting odor or experiencing nose or throat irritation. The outer prefilters should be changed if experiencing increased resistance to breathing. [Figure 9]

|

| Figure 9. Charcoal-filtered respirator |

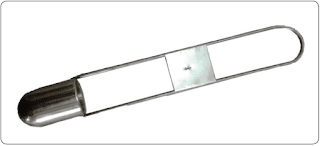

Viscosity Measuring Cup

This is a small cup with a long handle and a calibrated orifice in the bottom that allows the liquid in the cup to drain out at a specific timed rate. Coating manufacturers recommend spraying their product at a specific pressure and viscosity. That viscosity is determined by measuring the efflux (drain) time of the liquid coating through the cup orifice. The time (in seconds) is listed on most paint manufacturers’ product/technical data pages. The measurement determines if the mixed coating meets the recommended viscosity for spraying.There are different manufacturers of the viscosity measuring devices, but the most common one listed and used for spray painting is known as a Zahn cup. The orifice number must correspond to the one listed on the product/technical data sheet. For most primers and topcoats, the #2 or #3 Zahn cup is the one recommended. [Figure 10]

|

| Figure 10. A Zahn cup viscosity measuring cup |

To perform an accurate viscosity measurement, it is very important that the temperature of the sample material be within the recommended range of 73.5 °F ± 3.5 °F (23 ºC ± 2 ºC), and then proceed as follows:

- Thoroughly mix the sample with minimum bubbles.

- Dip the Zahn cup vertically into the sample being tested, totally immersing the cup below the surface.

- With a stopwatch in one hand, briskly lift the cup out of the sample. As the top edge of the cup breaks the surface, start the stopwatch.

- Stop the stopwatch when the first break in the flow of the liquid is observed at the orifice exit. The number in seconds is referred to as the efflux time.

- Record the time on the stopwatch and compare it to the coating manufacturer’s recommendation. Adjust the viscosity, if necessary, but be aware not to thin the coating below recommendations that could result in the release of VOCs into the atmosphere above the regulated limitations.

Mixing Equipment

Use a paint shaker for all coatings within 5 days of application to ensure the material is thoroughly mixed. Use a mechanical paint stirrer to mix larger quantities of material. If a mechanical stirrer is driven by a drill, the drill should be pneumatic, instead of electric. The sparks from an electric drill can cause an explosion from the paint vapors.