Seals are used to prevent fluid from passing a certain point, as well as to keep air and dirt out of the system in which they are used. The increased use of hydraulics and pneumatics in aircraft systems has created a need for packings and gaskets of varying characteristics and design to meet the many variations of operating speeds and temperatures to which they are subjected. No one style or type of seal is satisfactory for all installations. Some of the reasons for this are:

Seals are divided into three main classes: packings, gaskets, and wipers.

When O-ring packing is subjected to pressure from both sides, as in actuating cylinders, two backup rings must be used (one on either side of the O-ring). When an O-ring is subject to pressure on only one side, a single backup ring is generally used. In this case, the backup ring is always placed on the side of the O-ring away from the pressure.

The materials from which O-rings are manufactured have been compounded for various operating conditions, temperatures, and fluids. An O-ring designed specifically for use as a static (stationary) seal, probably will not do the job when installed on a moving part, such as a hydraulic piston. Most O-rings are similar in appearance and texture, but their characteristics may differ widely. An O-ring is useless if it is not compatible with the system fluid and operating temperature.

Advances in aircraft design have necessitated new O-ring compositions to meet changed operating conditions. Hydraulic O-rings were originally established under AN specification numbers (6227, 6230, and 6290) for use in MIL-H-5606 fluid at temperatures ranging from −65 °F to +160 °F. When new designs raised operating temperatures to a possible 275 °F, more compounds were developed and perfected.

Recently, a compound was developed that offered improved low-temperature performance without sacrificing high-temperature performance, rendering the other series obsolete. This superior material was adopted in the MS28775 series. This series is now the standard for MIL-H-5606 systems in which the temperature may vary from −65 °F to +275 °F.

Manufacturers provide color-coding on some O-rings, but this is not a reliable or complete means of identification. The color-coding system does not identify sizes but only system fluid or vapor compatibility and, in some cases, the manufacturer. Color codes on O-rings that are compatible with MIL-H-5606 fluid always contains blue but may also contain red or other colors. Packings and gaskets suitable for use with Skydrol™ fluid is always coded with a green stripe, but may also have a blue, grey, red, green, or yellow dot as a part of the color code. Color codes on O-rings that are compatible with hydrocarbon fluid always contains red but never contain blue. A colored stripe around the circumference indicates that the O-ring is a boss gasket seal. The color of the stripe indicates fluid compatibility: red for fuel, blue for hydraulic fluid.

The coding on some rings is not permanent. On others it may be omitted due to manufacturing difficulties or interference with operation. Furthermore, the color-coding system provides no means to establish the age of the O-ring or its temperature limitations.

Because of the difficulties with color-coding, O-rings are available in individual hermetically-sealed envelopes labeled with all pertinent data. When selecting an O-ring for installation, the basic part number on the sealed envelope provides the most reliable compound identification.

Although an O-ring may appear perfect at first glance, slight surface flaws may exist. These flaws are often capable of preventing satisfactory O-ring performance under the variable operating pressures of aircraft systems; therefore, O-rings should be rejected for flaws that affect their performance. Such flaws are difficult to detect, and one aircraft manufacturer recommends using a 4-power magnifying glass with adequate lighting to inspect each ring before it is installed.

By rolling the ring on an inspection cone or dowel, the inner diameter surface can also be checked for small cracks, particles of foreign material, or other irregularities that cause leakage or shorten the life of the O-ring. The slight stretching of the ring when it is rolled inside out helps to reveal some defects not otherwise visible.

The inspection of backup rings should include a check to ensure that surfaces are free from irregularities, that the edges are clean cut and sharp, and that scarf cuts are parallel. When checking Teflon™ spiral backup rings, make sure that the coils do not separate more than 1⁄4 inch when unrestrained.

A solid copper washer is used for spark plug gaskets where it is essential to have a non-compressible, yet semisoft gasket. Cork gaskets can be used as an oil seal between the engine crankcase and accessories, and where a gasket is required that can occupy an uneven or varying space caused by a rough surface or expansion and contraction.

Rubber sheeting can be used where there is a need for a compressible gasket. It should not be used in any place where it may come in contact with gasoline or oil because the rubber deteriorates very rapidly when exposed to these substances. Gaskets are used in fluid systems around the end caps of actuating cylinders, valves, and other units. The gasket generally used for this purpose is in the shape of an O-ring, similar to O-ring packings.

All sealant material should be carefully weighed in accordance with the sealant manufacturer’s recommendations. Sealant material is usually weighed with a balance scale equipped with weights specially prepared for various quantities of sealant and accelerator.

Before weighing the sealant materials, thoroughly stir both the base sealant compound and the accelerator. Do not use accelerator, which is dried out, lumpy, or flaky. Preweighed sealant kits do not require weighing of the sealant and accelerator before mixing when the entire quantity is to be mixed.

After determining the proper amount of base sealant compound and accelerator, add the accelerator to the base sealant compound. Immediately after adding the accelerator, thoroughly mix the two parts by stirring or folding, depending on the consistency of the material. Carefully mix the material to prevent entrapment of air in the mixture. Overly rapid or prolonged stirring builds up heat in the mixture and shortens the normal application time (working life) of the mixed sealant.

To ensure a well-mixed compound, test by smearing a small portion on a clean, flat metal, or glass surface. If flecks or lumps are found, continue mixing. If the flecks or lumps cannot be eliminated, reject the batch.

The working life of mixed sealant is from 1⁄2 hour to 4 hours (depending upon the class of sealant); therefore, apply mixed sealant as soon as possible or place in refrigerated storage. Figure 3 presents general information concerning various sealants.

The curing rate of mixed sealants varies with changes in temperature and humidity. Curing of sealants is extremely slow if the temperature is below 60 °F. A temperature of 77 °F with 50 percent relative humidity is the ideal condition for curing most sealants.

Curing may be accelerated by increasing the temperature, but the temperature should never be allowed to exceed 120 °F at any time in the curing cycle. Heat may be applied by using infrared lamps or heated air. If heated air is used, it must be properly filtered to remove moisture and dirt.

Heat should not be applied to any faying surface sealant installation until all work is completed. All faying surface applications must have all attachments, permanent or temporary, completed within the application limitations of the sealant.

Sealant must be cured to a tack-free condition before applying brush top coatings. (Tack-free consistency is the point at which a sheet of cellophane pressed onto the sealant no longer adheres.)

- Pressure at which the system operates

- Type fluid used in the system

- Metal finish and the clearance between adjacent parts

- Type motion (rotary or reciprocating), if any

Seals are divided into three main classes: packings, gaskets, and wipers.

Packings

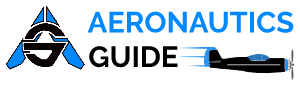

Packings are made of synthetic or natural rubber. They are generally used as “running seals,” that is, in units that contain moving parts, such as actuating cylinders, pumps, selector valves, and so forth. Packings are made in the form of O-rings, V-rings, and U-rings, each designed for a specific purpose. [Figure 1] |

| Figure 1. Packing rings |

O-Ring Packings

O-ring packings are used to prevent both internal and external leakage. This type of packing ring seals effectively in both directions and is the type most commonly used. In installations subject to pressures above 1,500 psi, backup rings are used with O-rings to prevent extrusion.When O-ring packing is subjected to pressure from both sides, as in actuating cylinders, two backup rings must be used (one on either side of the O-ring). When an O-ring is subject to pressure on only one side, a single backup ring is generally used. In this case, the backup ring is always placed on the side of the O-ring away from the pressure.

The materials from which O-rings are manufactured have been compounded for various operating conditions, temperatures, and fluids. An O-ring designed specifically for use as a static (stationary) seal, probably will not do the job when installed on a moving part, such as a hydraulic piston. Most O-rings are similar in appearance and texture, but their characteristics may differ widely. An O-ring is useless if it is not compatible with the system fluid and operating temperature.

Advances in aircraft design have necessitated new O-ring compositions to meet changed operating conditions. Hydraulic O-rings were originally established under AN specification numbers (6227, 6230, and 6290) for use in MIL-H-5606 fluid at temperatures ranging from −65 °F to +160 °F. When new designs raised operating temperatures to a possible 275 °F, more compounds were developed and perfected.

Recently, a compound was developed that offered improved low-temperature performance without sacrificing high-temperature performance, rendering the other series obsolete. This superior material was adopted in the MS28775 series. This series is now the standard for MIL-H-5606 systems in which the temperature may vary from −65 °F to +275 °F.

Manufacturers provide color-coding on some O-rings, but this is not a reliable or complete means of identification. The color-coding system does not identify sizes but only system fluid or vapor compatibility and, in some cases, the manufacturer. Color codes on O-rings that are compatible with MIL-H-5606 fluid always contains blue but may also contain red or other colors. Packings and gaskets suitable for use with Skydrol™ fluid is always coded with a green stripe, but may also have a blue, grey, red, green, or yellow dot as a part of the color code. Color codes on O-rings that are compatible with hydrocarbon fluid always contains red but never contain blue. A colored stripe around the circumference indicates that the O-ring is a boss gasket seal. The color of the stripe indicates fluid compatibility: red for fuel, blue for hydraulic fluid.

The coding on some rings is not permanent. On others it may be omitted due to manufacturing difficulties or interference with operation. Furthermore, the color-coding system provides no means to establish the age of the O-ring or its temperature limitations.

Because of the difficulties with color-coding, O-rings are available in individual hermetically-sealed envelopes labeled with all pertinent data. When selecting an O-ring for installation, the basic part number on the sealed envelope provides the most reliable compound identification.

Although an O-ring may appear perfect at first glance, slight surface flaws may exist. These flaws are often capable of preventing satisfactory O-ring performance under the variable operating pressures of aircraft systems; therefore, O-rings should be rejected for flaws that affect their performance. Such flaws are difficult to detect, and one aircraft manufacturer recommends using a 4-power magnifying glass with adequate lighting to inspect each ring before it is installed.

By rolling the ring on an inspection cone or dowel, the inner diameter surface can also be checked for small cracks, particles of foreign material, or other irregularities that cause leakage or shorten the life of the O-ring. The slight stretching of the ring when it is rolled inside out helps to reveal some defects not otherwise visible.

Backup Rings

Backup rings (MS28782) made of Teflon™ do not deteriorate with age, are unaffected by any system fluid or vapor, and can tolerate temperature extremes in excess of those encountered in high-pressure hydraulic systems. Their dash numbers indicate not only their size but also relate directly to the dash number of the O-ring for which they are dimensionally suited. They are procurable under several basic part numbers, but they are interchangeable; that is, any Teflon™ backup ring may be used to replace any other Teflon™ backup ring if it is of proper overall dimension to support the applicable O-ring. Backup rings are not color-coded or otherwise marked and must be identified from package labels.The inspection of backup rings should include a check to ensure that surfaces are free from irregularities, that the edges are clean cut and sharp, and that scarf cuts are parallel. When checking Teflon™ spiral backup rings, make sure that the coils do not separate more than 1⁄4 inch when unrestrained.

V-Ring Packings

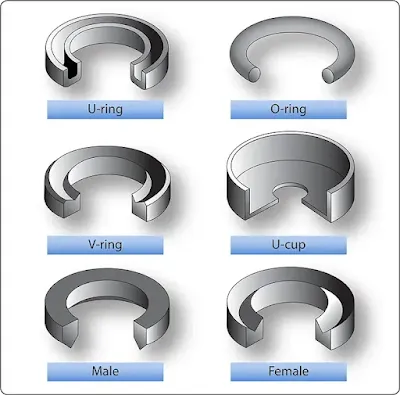

V-ring packings (AN6225) are one-way seals and are always installed with the open end of the “V” facing the pressure. V-ring packings must have a male and female adapter to hold them in the proper position after installation. It is also necessary to torque the seal retainer to the value specified by the manufacturer of the component being serviced, or the seal may not give satisfactory service. An installation using V-rings is shown in Figure 2. |

| Figure 2. V-ring installation |

U-Ring Packings

U-ring packings (AN6226) and U-cup packings are used in brake assemblies and brake master cylinders. The U-ring and U-cup seal pressure in only one direction; therefore, the lip of the packings must face toward the pressure. U-ring packings are primarily low-pressure packings to be used with pressures of less than 1,000 psi.Gaskets

Gaskets are used as static (stationary) seals between two flat surfaces. Some of the more common gasket materials are asbestos, copper, cork, and rubber. Asbestos sheeting is used wherever a heat-resistant gasket is needed. It is used extensively for exhaust system gaskets. Most asbestos exhaust gaskets have a thin sheet of copper edging to prolong their life.A solid copper washer is used for spark plug gaskets where it is essential to have a non-compressible, yet semisoft gasket. Cork gaskets can be used as an oil seal between the engine crankcase and accessories, and where a gasket is required that can occupy an uneven or varying space caused by a rough surface or expansion and contraction.

Rubber sheeting can be used where there is a need for a compressible gasket. It should not be used in any place where it may come in contact with gasoline or oil because the rubber deteriorates very rapidly when exposed to these substances. Gaskets are used in fluid systems around the end caps of actuating cylinders, valves, and other units. The gasket generally used for this purpose is in the shape of an O-ring, similar to O-ring packings.

Wipers

Wipers are used to clean and lubricate the exposed portions of piston shafts. They prevent dirt from entering the system and help protect the piston shaft against scoring. Wipers may be either metallic or felt. They are sometimes used together, a felt wiper installed behind a metallic wiper.Sealing Compounds

Certain areas of all aircraft are sealed to withstand pressurization by air, to prevent leakage of fuel, to prevent passage of fumes, or to prevent corrosion by sealing against the weather. Most sealants consist of two or more ingredients properly proportioned and compounded to obtain the best results. Some materials are ready for use as packaged, but others require mixing before application.One Part Sealants

One part sealants are prepared by the manufacturer and are ready for application as packaged. However, the consistency of some of these compounds may be altered to satisfy a particular method of application. If thinning is desired, use the thinner recommended by the sealant manufacturer.Two Part Sealants

Two part sealants are compounds requiring separate packaging to prevent cure prior to application and are identified as the base sealing compound and the accelerator. Any alteration of the prescribed ratios reduces the quality of the material. Combining equal portions, by weight, of base compound and accelerator, mixes two part sealants.All sealant material should be carefully weighed in accordance with the sealant manufacturer’s recommendations. Sealant material is usually weighed with a balance scale equipped with weights specially prepared for various quantities of sealant and accelerator.

Before weighing the sealant materials, thoroughly stir both the base sealant compound and the accelerator. Do not use accelerator, which is dried out, lumpy, or flaky. Preweighed sealant kits do not require weighing of the sealant and accelerator before mixing when the entire quantity is to be mixed.

After determining the proper amount of base sealant compound and accelerator, add the accelerator to the base sealant compound. Immediately after adding the accelerator, thoroughly mix the two parts by stirring or folding, depending on the consistency of the material. Carefully mix the material to prevent entrapment of air in the mixture. Overly rapid or prolonged stirring builds up heat in the mixture and shortens the normal application time (working life) of the mixed sealant.

To ensure a well-mixed compound, test by smearing a small portion on a clean, flat metal, or glass surface. If flecks or lumps are found, continue mixing. If the flecks or lumps cannot be eliminated, reject the batch.

The working life of mixed sealant is from 1⁄2 hour to 4 hours (depending upon the class of sealant); therefore, apply mixed sealant as soon as possible or place in refrigerated storage. Figure 3 presents general information concerning various sealants.

|

| Figure 3. General sealant information |

The curing rate of mixed sealants varies with changes in temperature and humidity. Curing of sealants is extremely slow if the temperature is below 60 °F. A temperature of 77 °F with 50 percent relative humidity is the ideal condition for curing most sealants.

Curing may be accelerated by increasing the temperature, but the temperature should never be allowed to exceed 120 °F at any time in the curing cycle. Heat may be applied by using infrared lamps or heated air. If heated air is used, it must be properly filtered to remove moisture and dirt.

Heat should not be applied to any faying surface sealant installation until all work is completed. All faying surface applications must have all attachments, permanent or temporary, completed within the application limitations of the sealant.

Sealant must be cured to a tack-free condition before applying brush top coatings. (Tack-free consistency is the point at which a sheet of cellophane pressed onto the sealant no longer adheres.)

RELATED POSTS