A secondary function of the compressor is to supply bleed-air for various purposes in the engine and aircraft. The bleed-air is taken from any of the various pressure stages of the compressor. The exact location of the bleed ports is, of course, dependent on the pressure or temperature required for a particular job. The ports are small openings in the compressor case adjacent to the particular stage from which the air is to be bled; thus, varying degrees of pressure are available simply by tapping into the appropriate stage. Air is often bled from the final or highest pressure stage since, at this point, pressure and air temperature are at a maximum. At times it may be necessary to cool this high-pressure air. If it is used for cabin pressurization or other purposes to which excess heat would be uncomfortable or detrimental, the air is sent through an air conditioning unit before it enters the cabin. Bleed air is utilized in a wide variety of ways. Some of the current applications of bleed air are:

- Cabin pressurization, heating, and cooling

- Deicing and anti-icing equipment

- Pneumatic starting of engines

- Auxiliary drive units (ADU)

Compressor Types

The two principal types of compressors currently being used in gas turbine aircraft engines are centrifugal flow and axial flow. The centrifugal-flow compressor achieves its purpose by picking up the entering air and accelerating it outwardly by centrifugal action. The axial-flow compressor compresses air while the air continues in its original direction of flow, thus avoiding the energy loss caused by turns. The components of each of these two types of compressor have their individual functions in the compression of air for the combustion section. A stage in a compressor is considered to be a rise in pressure.Centrifugal-Flow Compressors

The centrifugal-flow compressor consists of an impeller (rotor), a diffuser (stator), and a compressor manifold. [Figure 1] Centrifugal compressors have a high pressure rise per stage that can be around 8:1. Generally centrifugal compressors are limited to two stages due to efficiency concerns. The two main functional elements are the impeller and the diffuser. Although the diffuser is a separate unit and is placed inside and bolted to the manifold, the entire assembly (diffuser and manifold) is often referred to as the diffuser. For clarification during compressor familiarization, the units are treated individually. The impeller is usually made from forged aluminum alloy, heat treated, machined, and smoothed for minimum flow restriction and turbulence. |

| Figure 1. (A) Components of a centrifugal-flow compressor; (B) Air outlet elbow with turning vanes for reducing air pressure losses |

In most types, the impeller is fabricated from a single forging. This type impeller is shown in Figure 1. The impeller, whose function is to pick up and accelerate the air outwardly to the diffuser, may be either of two types—single entry or double entry. The principal differences between the two types of impellers are size and ducting arrangement. The double-entry type has a smaller diameter, but is usually operated at a higher rotational speed to assure sufficient airflow. The single-entry impeller, shown in Figure 2, permits convenient ducting directly to the impeller eye (inducer vanes) as opposed to the more complicated ducting necessary to reach the rear side of the double-entry type. Although slightly more efficient in receiving air, the single-entry impeller must be large in diameter to deliver the same quantity of air as the double-entry type. This, of course, increases the overall diameter of the engine.

|

| Figure 2. Single-entry impeller |

Included in the ducting for double-entry compressor engines is the plenum chamber. This chamber is necessary for a double-entry compressor because the air must enter the engine at almost right angles to the engine axis. Therefore, in order to give a positive flow, the air must surround the engine compressor at a positive pressure before entering the compressor. Included in some installations as necessary parts of the plenum chamber are the auxiliary air-intake doors (blow-in doors). These blow-in doors admit air to the engine compartment during ground operation, when air requirements for the engine are in excess of the airflow through the inlet ducts. The doors are held closed by spring action when the engine is not operating. During operation, however, the doors open automatically whenever engine compartment pressure drops below atmospheric pressure. During takeoff and flight, ram air pressure in the engine compartment aids the springs in holding the doors closed.

The diffuser is an annular chamber provided with a number of vanes forming a series of divergent passages into the manifold. The diffuser vanes direct the flow of air from the impeller to the manifold at an angle designed to retain the maximum amount of energy imparted by the impeller. They also deliver the air to the manifold at a velocity and pressure satisfactory for use in the combustion chambers. Refer to Figure 1-A and note the arrow indicating the path of airflow through the diffuser, then through the manifold.

The compressor manifold shown in Figure 1-A diverts the flow of air from the diffuser, which is an integral part of the manifold, into the combustion chambers. The manifold has one outlet port for each chamber so that the air is evenly divided. A compressor outlet elbow is bolted to each of the outlet ports. These air outlets are constructed in the form of ducts and are known by a variety of names, such as air outlet ducts, outlet elbows, or combustion chamber inlet ducts. Regardless of the terminology used, these outlet ducts perform a very important part of the diffusion process; that is, they change the radial direction of the airflow to an axial direction, in which the diffusion process is completed after the turn. To help the elbows perform this function in an efficient manner, turning vanes (cascade vanes) are sometimes fitted inside the elbows. These vanes reduce air pressure losses by presenting a smooth, turning surface. [Figure 1-B]

The diffuser is an annular chamber provided with a number of vanes forming a series of divergent passages into the manifold. The diffuser vanes direct the flow of air from the impeller to the manifold at an angle designed to retain the maximum amount of energy imparted by the impeller. They also deliver the air to the manifold at a velocity and pressure satisfactory for use in the combustion chambers. Refer to Figure 1-A and note the arrow indicating the path of airflow through the diffuser, then through the manifold.

The compressor manifold shown in Figure 1-A diverts the flow of air from the diffuser, which is an integral part of the manifold, into the combustion chambers. The manifold has one outlet port for each chamber so that the air is evenly divided. A compressor outlet elbow is bolted to each of the outlet ports. These air outlets are constructed in the form of ducts and are known by a variety of names, such as air outlet ducts, outlet elbows, or combustion chamber inlet ducts. Regardless of the terminology used, these outlet ducts perform a very important part of the diffusion process; that is, they change the radial direction of the airflow to an axial direction, in which the diffusion process is completed after the turn. To help the elbows perform this function in an efficient manner, turning vanes (cascade vanes) are sometimes fitted inside the elbows. These vanes reduce air pressure losses by presenting a smooth, turning surface. [Figure 1-B]

[ad-mid]

Axial-Flow Compressor

The axial-flow compressor has two main elements: a rotor and a stator. The rotor has blades fixed on a spindle. These blades impel air rearward in the same manner as a propeller because of their angle and airfoil contour. The rotor, turning at high speed, takes in air at the compressor inlet and impels it through a series of stages. From inlet to exit, the air flows along an axial path and is compressed at a ratio of approximately 1.25:1 per stage. The action of the rotor increases the compression of the air at each stage and accelerates it rearward through several stages. With this increased velocity, energy is transferred from the compressor to the air in the form of velocity energy. The stator blades act as diffusers at each stage, partially converting high velocity to pressure. Each consecutive pair of rotor and stator blades constitutes a pressure stage. The number of rows of blades (stages) is determined by the amount of air and total pressure rise required. Compressor pressure ratio increases with the number of compression stages. Most engines utilize up to 16 stages and more.The stator has rows of vanes, which are in turn attached inside an enclosing case. The stator vanes, which are stationary, project radially toward the rotor axis and fit closely on either side of each stage of the rotor blades. In some cases, the compressor case, into which the stator vanes are fitted, is horizontally divided into halves. Either the upper or lower half may be removed for inspection or maintenance of rotor and stator blades.

The function of the stator vanes is to receive air from the air inlet duct or from each preceding stage and increase the pressure of the air and deliver it to the next stage at the correct velocity and pressure. They also control the direction of air to each rotor stage to obtain the maximum possible compressor blade efficiency. Shown in Figure 3 are the rotor and stator elements of a typical axial-flow compressor. The first stage rotor blades can be preceded by an inlet guide vane assembly that can be fixed or variable.

|

| Figure 3. Rotor and stator elements of a typical axial-flow compressor |

The guide vanes direct the airflow into the first stage rotor blades at the proper angle and impart a swirling motion to the air entering the compressor. This preswirl, in the direction of engine rotation, improves the aerodynamic characteristics of the compressor by reducing drag on the first stage rotor blades. The inlet guide vanes are curved steel vanes usually welded to steel inner and outer shrouds.

At the discharge end of the compressor, the stator vanes are constructed to straighten the airflow to eliminate turbulence. These vanes are called straightening vanes or the outlet vane assembly. The casings of axial-flow compressors not only support the stator vanes and provide the outer wall of the axial path the air follows, but they also provide the means for extracting compressor air for various purposes. The stator vanes are usually made of steel with corrosion- and erosion-resistant qualities. Quite frequently, they are shrouded (enclosed) by a band of suitable material to simplify the fastening problem. The vanes are welded into the shrouds, and the outer shroud is secured to the compressor housing inner wall by radial retaining screws.

At the discharge end of the compressor, the stator vanes are constructed to straighten the airflow to eliminate turbulence. These vanes are called straightening vanes or the outlet vane assembly. The casings of axial-flow compressors not only support the stator vanes and provide the outer wall of the axial path the air follows, but they also provide the means for extracting compressor air for various purposes. The stator vanes are usually made of steel with corrosion- and erosion-resistant qualities. Quite frequently, they are shrouded (enclosed) by a band of suitable material to simplify the fastening problem. The vanes are welded into the shrouds, and the outer shroud is secured to the compressor housing inner wall by radial retaining screws.

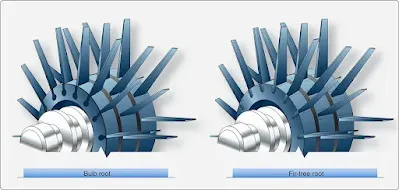

The rotor blades are usually made of stainless steel with the latter stages being made of titanium. The design of blade attachment to the rotor disk rims varies, but they are commonly fitted into disks by either bulb-type or fir-tree methods. [Figure 4] The blades are then locked into place by differing methods. Compressor blade tips are reduced in thickness by cutouts, referred to as blade profiles. These profiles prevent serious damage to the blade or housing should the blades contact the compressor housing. This condition can occur if rotor blades become excessively loose or if rotor support is reduced by a malfunctioning bearing. Even though blade profiles greatly reduce such possibilities, occasionally a blade may break under stress of rubbing and cause considerable damage to compressor blades and stator vane assemblies. The blades vary in length from entry to discharge because the annular working space (drum to casing) is reduced progressively toward the rear by the decrease in the casing diameter. [Figure 5] This feature provides for a fairly constant velocity through the compressor, which helps to keep the flow of air constant.

|

| Figure 4. Common designs of compressor blade attachment to the rotor disk |

|

| Figure 5. Drum-type compressor rotor |

|

| Figure 6. Disk-type compressor rotor |

The combination of the compressor stages and turbine stages on a common shaft is an engine referred to as an engine spool. The common shaft is provided by joining the turbine and compressor shafts by a suitable method. The engine’s spool is supported by bearings, which are seated in suitable bearing housings.

As mentioned earlier, there are two configurations of the axial compressor currently in use: the single rotor/spool and the dual rotor/spool, sometimes referred to as solid spool and split spool (two spool, dual spool).

One version of the solid-spool (one spool) compressor uses variable inlet guide vanes. Also, the first few rows of stator vanes are variable. The main difference between variable inlet guide vane (VIGV) and a variable stator vane (VSV) is their position with regard to the rotor blades. VIGV are in front of the rotor blades, and VSV are behind the rotor blades. The angles of the inlet guide vanes and the first several stages of the stator vanes are can be variable. During operation, air enters the front of the engine and is directed into the compressor at the proper angle by the variable inlet guide and directed by the VSV. The air is compressed and forced into the combustion section. A fuel nozzle that extends into each combustion liner atomizes the fuel for combustion. These variables are controlled in direct relation to the amount of power the engine is required to produce by the power lever position.

Most turbofan engines are of the split-spool compressor type. Most large turbofan engines use a large fan with a few stages of compression called the low-pressure spool. These turbofans incorporate two compressors with their respective turbines and interconnecting shafts, which form two physically independent rotor systems. Many dual rotor systems have rotors turning in opposite directions and with no mechanical connection to each other. The second spool, referred to as the high-pressure spool and is the compressor for the gas generator and core of the engine, supplies air to the combustion section of the engine.

The advantages and disadvantages of both types of compressors are included in the following list. Even though each type has advantages and disadvantages, each has its use by type and size of engine.

The centrifugal-flow compressor’s advantages are:

The centrifugal-flow compressor’s disadvantages are:

The axial-flow compressor’s advantages are:

The axial-flow compressor’s disadvantages are:

RELATED POSTS

The advantages and disadvantages of both types of compressors are included in the following list. Even though each type has advantages and disadvantages, each has its use by type and size of engine.

The centrifugal-flow compressor’s advantages are:

- High pressure rise per stage

- Efficiency over wide rotational speed range

- Simplicity of manufacture and low cost

- Low weight

- Low starting power requirements.

The centrifugal-flow compressor’s disadvantages are:

- Its large frontal area for a given airflow

- Losses in turns between stages

The axial-flow compressor’s advantages are:

- High peak efficiencies

- Small frontal area for given airflow

- Straight-through flow, allowing high ram efficiency

- Increased pressure rise by increasing number of stages, with negligible losses

The axial-flow compressor’s disadvantages are:

- Good efficiencies over only narrow rotational speed range

- Difficulty of manufacture and high cost

- Relatively high weight

- High starting power requirements (partially overcome by split compressors)

RELATED POSTS