While each manufacturer designs its own fuel system, the basic fuel system requirements referenced at the beginning of this site yield fuel systems of similar design and function in the field. In the following sections are representative examples of various fuel systems in each class of aircraft discussed. Others are similar but not identical. Each aircraft fuel system must store and deliver clean fuel to the engine(s) at a pressure and flow rate able to sustain operations regardless of the operating conditions of the aircraft.

Small Single Engine Aircraft Fuel Systems

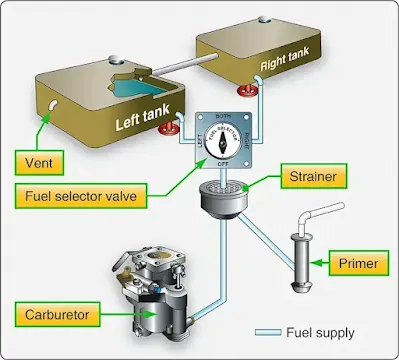

Small single-engine aircraft fuel systems vary depending on factors, such as tank location and method of metering fuel to the engine. A high-wing aircraft fuel system can be designed differently from one on a low-wing aircraft. An aircraft engine with a carburetor has a different fuel system than one with fuel injection.Gravity Feed Systems

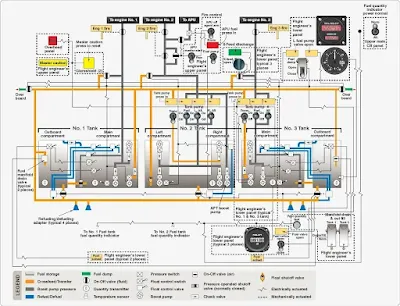

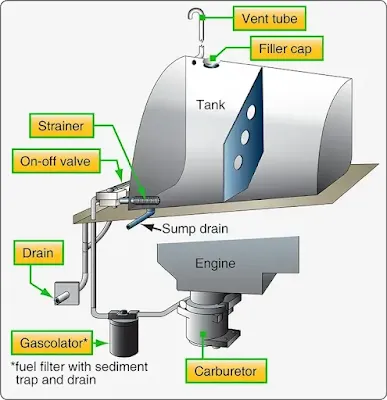

High-wing aircraft with a fuel tank in each wing are common. With the tanks above the engine, gravity is used to deliver the fuel. A simple gravity feed fuel system is shown in Figure 1. |

| Figure 1. The gravity-feed fuel system in a single-engine highwing aircraft is the simplest aircraft fuel system |

The space above the liquid fuel is vented to maintain atmospheric pressure on the fuel as the tank empties. The two tanks are also vented to each other to ensure equal pressure when both tanks feed the engine. A single screened outlet on each tank feeds lines that connect to either a fuel shutoff valve or multiposition selector valve. The shutoff valve has two positions: fuel ON and fuel OFF. If installed, the selector valve provides four options: fuel shutoff to the engine; fuel feed from the right wing tank only; fuel feed from the left fuel tank only; fuel feed to the engine from both tanks simultaneously.

Downstream of the shutoff valve or selector valve, the fuel passes through a main system strainer. This often has a drain function to remove sediment and water. From there, it flows to the carburetor or to the primer pump for engine starting. Having no fuel pump, the gravity feed system is the simplest aircraft fuel system.

From the selector valve (LEFT, RIGHT, or OFF), fuel flows through the main strainer where it can supply the engine primer. Then, it flows downstream to the fuel pumps. Typically, one electric and one engine-driven fuel pump are arranged in parallel. They draw the fuel from the tank(s) and deliver it to the carburetor. The two pumps provide redundancy. The engine-driven fuel pump acts as the primary pump. The electric pump can supply fuel should the other fail.

The electric pump also supplies fuel pressure while starting and is used to prevent vapor lock during flight at high altitude.

NOTE: Fuel injection systems spray pressurized fuel into the engine intake or directly into the cylinders. Fuel without any air mixed in is required to provide a measured, continuous spray and smooth engine operation.

Fuel pressurized by an engine-driven pump is metered as a function of engine rpm on the Teledyne-Continental system. It is first delivered from the fuel tanks by gravity to two smaller accumulator or reservoir tanks. These tanks, one for each wing tank, consolidate the liquid fuel and have a relatively small airspace. They deliver fuel through a three-way selector valve (LEFT, RIGHT, or OFF). The selector valve also acts simultaneously as a diverter of air that has been separated out of the fuel in the engine-driven fuel pump and returned to the valve. It routes the air to the vent space above the fuel in the selected reservoir tank.

An electric auxiliary fuel pump draws fuel through the selector valve. It forces the fuel through the strainer, making it available for the primer pump and the engine-driven fuel pump. This pump is typically used for starting and as a backup should the engine-driven pump fail. It is controlled by a switch in the cockpit and does not need to be operating to allow the engine-driven fuel pump access to the fuel.

The engine-driven fuel pump intakes the pressurized fuel from the electrically driven pump or from the reservoir tanks if the electric pump is not operating. It supplies a higher-than needed volume of fuel under pressure to the fuel control. Excess fuel is returned to the pump, which pumps it through the selector valve into the appropriate reservoir tank. Fuel vapor is also returned to tanks by the pump. The fuel control unit meters the fuel according to engine rpm and mixture control inputs from the cockpit.

The fuel control delivers the fuel to the distribution manifold, which divides it and provides equal, consistent fuel flow for individual fuel injector in each cylinder. [Figure 4] A fuel flow indicator tapped off of the distribution manifold provides feedback in cockpit. It senses fuel pressure but is displayed on a dial calibrated in gallons per hour.

Two selector valves are required on twin-engine aircraft, one for each engine. The right selector valve receives fuel from a main tank on either side of the aircraft and directs it to the right engine. The left selector valve also receives fuel from either main tank and directs it to the left engine. This allows fuel to crossfeed from one side of the aircraft to the opposite engine if desired. The selector valves can also direct fuel from the auxilliary tank to the engine on the same side. Crossfeed of fuel from auxilliary tanks is not possible. From the outlet of the selector valve, fuel flows to the strainer. On some aircraft, the strainer is built into the selector valve unit. From the strainer, fuel flows to the engine-driven fuel pump.

The engine-driven fuel pump is an assembly that also contains a vapor separator and a pressure regulating valve with an adjustment screw. The vapor separator helps eliminate air from the fuel. It returns a small amount of fuel and any vapor present back to the main fuel tank. The pump supplies pressurized fuel to the fuel control. The fuel control, one for each engine, responds to throttle and mixture control settings from the cockpit and supplies the proper amount of fuel to the fuel manifold. The manifold divides the fuel and sends it to an injector in each cylinder. A fuel pressure gauge is placed between the fuel control unit outlet and the manifold to monitor the injector-applied pressure that indicates engine power.

Figure 7 shows the fuel system of a DC-3. A selector valve for each engine allows an engine-driven pump to pull fuel from the main tank or an auxiliary tank. The fuel passes through a strainer before reaching the pump where it is delivered to the engine. The outlet of the pump can feed either engine through the use of a crossfeed line with valves controlled in the cockpit. A hand-operated wobble pump located upstream of the strainer is used to prime the system for starting. Fuel vapor lines run from the pressure carburetor to the vent space in the main and auxilliary tanks. Fuel pressure gauges are tapped off of the carburetor for power indication.

The hand-operated wobble pumps were replaced by electric pumps on later model aircraft. A fuel pressure warning light tapped in downstream of the engine-driven fuel pump alerts the crew should fuel pressure decline.

Not all large, old aircraft have this fuel system. This is merely an example. Others aircraft share similar features and possess unique features of their own. The same is true for small reciprocating-engine aircraft. There are many systems that share features with those described above, but they also differ in some ways. Always consult the manufacturer’s data when working on aircraft fuel systems and follow all instructions for service and repair. The fuel system of an aircraft provides the life blood for engine operation and must be maintained with the highest discretion.

Jet transport fuel systems can be regarded as a handful of fuel subsystems as follows:

Most transport category aircraft fuel systems are very much alike. Integral fuel tanks are the norm with much of each wing’s structure sealed to enable its use as a fuel tank. Center wing section or fuselage tanks are also common. These may be sealed structure or bladder type. Jet transport aircraft carry tens of thousands of pounds of fuel on board. Figure 8 shows a diagram of a Boeing 777 fuel tank configuration with tank capacities.

Note that there are optional fuel storage configurations available on the same model airliner. For example, airlines expecting to use an aircraft on transoceanic flights may order the aircraft with long-range auxiliary tanks. These additional tanks, usually located in the fuselage section of the aircraft, can alter fuel management logistics in addition to complicating the fuel system.

In addition to main and auxiliary fuel tanks, surge tanks may also be found on jet transports. These normally empty tanks located in the wing structure outboard of the main wing tanks are used for fuel overflow. A check valve allows the one-way drainage of fuel back into the main tanks. Surge tanks are also use for fuel system venting.

Transport category fuel systems require venting similar to reciprocating engine aircraft fuel systems. A series of vent tubing and channels exists that connects all tanks to vent space in the surge tanks (if present) or vent overboard. Venting must be configured to ensure the fuel is vented regardless of the attitude of the aircraft or the quantity of fuel on board. This sometimes requires the installation of various check valves, float valves, and multiple vent locations in the same tank. Figure 9 shows the fuel vent system of a Boeing 737.

A transport category aircraft fuel distribution subsystem consists of the pressure fueling components, defueling components, transfer system, and fuel jettison or dump system. Single-point pressure fueling at a fueling station accessible by ramp refueling trucks allows all aircraft fuel tanks to be filled with one connection of the fuel hose. Leading and trailing edge wing locations are common for these stations. Figure 10 shows an airliner fueling station with the fueling rig attached.

To fuel with pressure refueling, a hose nozzle is attached at the fueling station and valves to the tanks required to be filled are opened. These valves are called fueling valves or refueling valves depending upon the manufacturer’s preference. Various automatic shutoff systems have been designed to close tank fueling valves before the tanks overfill or are damaged. Gauges on the refueling panel allow refueling personnel to monitor progress.

Occasionally, defueling the aircraft is required for an inspection or repair. The same fueling station is used, and the hose from the fuel truck is connected to same receptacle used to fuel the aircraft. To allow fuel to exit the aircraft, a defueling valve is opened. Fuel can either be pumped out of the aircraft using the boost pumps located in the tanks that need to be emptied, or the pump in the refueling truck can be used to draw the fuel out of the tanks. Control over the operation is maintained by positioning various shutoff and crossfeed valves, as well as the defuel valve so that fuel travels from the tank to the fueling station and into the truck.

Figure 11 shows the fuel system diagram for a DC-10. Dedicated transfer boost pumps move fuel into a transfer manifold. Opening the fuel valve on one of the tanks transfers the fuel into that tank. The transfer manifold and boost pumps are also used to jettison fuel overboard by opening the proper dump valves with a transfer boost pump(s) operating. Additionally, the transfer system can function to supply the engines if the normal engine fuel feed malfunctions.

The fuel feed subsystem is sometimes considered part of the fuel distribution system. It is the heart of the fuel system since it delivers fuel to the engines. Jet transport aircraft supply fuel to the engines via in-tank fuel boost pumps, usually two per tank. They pump fuel under pressure through a shutoff valve for each engine. A manifold or connecting tubing typically allows any tank to supply any engine through the use of crossfeed valves. Boost pump bypasses allow fuel flow should a pump fail. Note that the engines are designed to be able to run without any fuel boost pumps operating. But, each engine’s shutoff valve must be open to allow flow to the engines from the tanks.

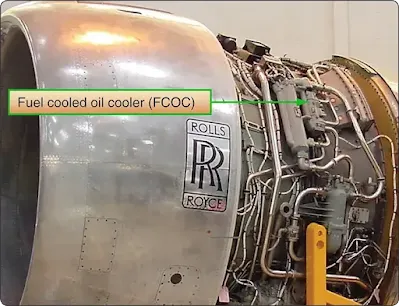

Most jet transport fuel feed systems, or the engine fuel systems, have some means for heating the fuel usually through an exchange with hot air or hot oil taken from the engine. Figure 12 shows the fuel cooled oil cooler (FCOC) on a Rolls Royce RB21 1 engine, which not only heats the fuel but also cools the engine oil.

Fuel indicating systems on jet transport aircraft monitor a variety of parameters, some not normally found on general aviation aircraft. Business jet aircraft share many of these features. True fuel flow indicators for each engine are used as the primary means for monitoring fuel delivery to the engines. A fuel temperature gauge is common as are fuel filter bypass warning lights. The temperature sensor is usually located in a main fuel tank. The indicator is located on the instrument panel or is displayed on a multifunction display (MFD). These allow the crew to monitor the fuel temperature during high altitude flight in extremely frigid conditions. The fuel filters have bypasses that permit fuel flow around the filters if clogged. Indicator light(s) illuminate in the cockpit when this occurs.

Low fuel pressure warning lights are also common on jet transport aircraft. The sensors for these are located in the boost pump outlet line. They give an indication of possible boost pump failure.

Fuel quantity gauges are important features on all aircraft. Indications exist for all tanks on a transport category aircraft. Often, these use a capacitance type fuel quantity indication system and a fuel totalizer as is discussed in Fuel System Indicators section.

The location of fuel instrumentation varies depending on the type of cockpit displays utilized on the aircraft.

Typically, a helicopter has only one or two fuel tanks located near the center of gravity (CG) of the aircraft, which is near the main rotor mast. Thus, the tank, or tanks, are usually located in or near the aft fuselage. Some helicopter fuel tanks are mounted above the engine allowing for gravity fuel feed. Others use fuel pumps and pressure feed systems.

Fundamentally, helicopter fuel systems differ little from those on fixed-wing aircraft. Gravity-feed systems have vented fuel tanks with an outlet strainer and shutoff valve. Fuel flows from the tank through a main filter to the carburetor. [Figure 13]

A slightly more complex system for a light turbine-powered helicopter is shown in Figure 14. Two in-tank electric boost pumps send fuel through a shutoff valve rather than a selector valve, since there is only one fuel tank. It flows through an airframe filter to an engine filter and then to the engine-driven fuel pump. The fuel tank is vented and contains an electrically operated sump drain valve. A pressure gauge is used to monitor boost pump output pressure and differential pressure switches warn of fuel filter restrictions. Fuel quantity is derived through the use of two in-tank fuel probes with transmitters.

Larger, heavy, multiengine transport helicopters have complex fuel systems similar to jet transport fixed-wing aircraft. They may feature multiple fuel tanks, crossfeed systems, and pressure refueling.

RELATED POSTS

Downstream of the shutoff valve or selector valve, the fuel passes through a main system strainer. This often has a drain function to remove sediment and water. From there, it flows to the carburetor or to the primer pump for engine starting. Having no fuel pump, the gravity feed system is the simplest aircraft fuel system.

Pump Feed Systems

Low- and mid-wing single reciprocating engine aircraft cannot utilize gravity-feed fuel systems because the fuel tanks are not located above the engine. Instead, one or more pumps are used to move the fuel from the tanks to the engine. A common fuel system of this type is shown in Figure 2. Each tank has a line from the screened outlet to a selector valve. However, fuel cannot be drawn from both tanks simultaneously; if the fuel is depleted in one tank, the pump would draw air from that tank instead of fuel from the full tank. Since fuel is not drawn from both tanks at the same time, there is no need to connect the tank vent spaces together. |

| Figure 2. A single reciprocating engine aircraft with fuel tanks located in wings below the engine uses pumps to draw fuel from the tanks and deliver it to the engine |

From the selector valve (LEFT, RIGHT, or OFF), fuel flows through the main strainer where it can supply the engine primer. Then, it flows downstream to the fuel pumps. Typically, one electric and one engine-driven fuel pump are arranged in parallel. They draw the fuel from the tank(s) and deliver it to the carburetor. The two pumps provide redundancy. The engine-driven fuel pump acts as the primary pump. The electric pump can supply fuel should the other fail.

The electric pump also supplies fuel pressure while starting and is used to prevent vapor lock during flight at high altitude.

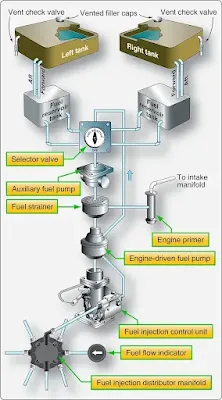

High Wing Aircraft With Fuel Injection System

Some high-wing, high-performance, single-engine general aviation aircraft are equipped with a fuel system that features fuel injection rather than a carburetor. It combines gravity flow with the use of a fuel pump(s). The Teledyne-Continental system is an example. [Figure 3] |

| Figure 3. A Teledyne-Continental fuel system featuring fuel injection used on high-wing, high-performance single-engine aircraft |

NOTE: Fuel injection systems spray pressurized fuel into the engine intake or directly into the cylinders. Fuel without any air mixed in is required to provide a measured, continuous spray and smooth engine operation.

Fuel pressurized by an engine-driven pump is metered as a function of engine rpm on the Teledyne-Continental system. It is first delivered from the fuel tanks by gravity to two smaller accumulator or reservoir tanks. These tanks, one for each wing tank, consolidate the liquid fuel and have a relatively small airspace. They deliver fuel through a three-way selector valve (LEFT, RIGHT, or OFF). The selector valve also acts simultaneously as a diverter of air that has been separated out of the fuel in the engine-driven fuel pump and returned to the valve. It routes the air to the vent space above the fuel in the selected reservoir tank.

An electric auxiliary fuel pump draws fuel through the selector valve. It forces the fuel through the strainer, making it available for the primer pump and the engine-driven fuel pump. This pump is typically used for starting and as a backup should the engine-driven pump fail. It is controlled by a switch in the cockpit and does not need to be operating to allow the engine-driven fuel pump access to the fuel.

The engine-driven fuel pump intakes the pressurized fuel from the electrically driven pump or from the reservoir tanks if the electric pump is not operating. It supplies a higher-than needed volume of fuel under pressure to the fuel control. Excess fuel is returned to the pump, which pumps it through the selector valve into the appropriate reservoir tank. Fuel vapor is also returned to tanks by the pump. The fuel control unit meters the fuel according to engine rpm and mixture control inputs from the cockpit.

The fuel control delivers the fuel to the distribution manifold, which divides it and provides equal, consistent fuel flow for individual fuel injector in each cylinder. [Figure 4] A fuel flow indicator tapped off of the distribution manifold provides feedback in cockpit. It senses fuel pressure but is displayed on a dial calibrated in gallons per hour.

|

| Figure 3. A Teledyne-Continental fuel system featuring fuel injection used on high-wing, high-performance single-engine aircraft |

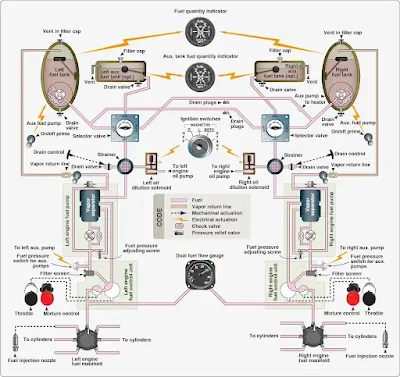

Small Multi engine (Reciprocating) Aircraft Fuel Systems

Low-Wing Twin

The fuel system on a small, multiengine aircraft is more complicated than a single-engine aircraft but contains many of the same elements. An example system used on a low-wing aircraft is illustrated in Figure 5. It features the main fuel tanks in the wing tips and auxiliary tanks in the wing structure. A boost pump is located at the outlet of each main tank. This pressurizes the entire fuel system from the tank to the injectors eliminating the possibility of vapor lock. An engine can operate with just its boost pump running in the event the engine-driven injection pump fails. Typically, the boost pumps are used to prime and start the engine. |

| Figure 5. A low-wing, twin-engine, light aircraft fuel system |

Two selector valves are required on twin-engine aircraft, one for each engine. The right selector valve receives fuel from a main tank on either side of the aircraft and directs it to the right engine. The left selector valve also receives fuel from either main tank and directs it to the left engine. This allows fuel to crossfeed from one side of the aircraft to the opposite engine if desired. The selector valves can also direct fuel from the auxilliary tank to the engine on the same side. Crossfeed of fuel from auxilliary tanks is not possible. From the outlet of the selector valve, fuel flows to the strainer. On some aircraft, the strainer is built into the selector valve unit. From the strainer, fuel flows to the engine-driven fuel pump.

The engine-driven fuel pump is an assembly that also contains a vapor separator and a pressure regulating valve with an adjustment screw. The vapor separator helps eliminate air from the fuel. It returns a small amount of fuel and any vapor present back to the main fuel tank. The pump supplies pressurized fuel to the fuel control. The fuel control, one for each engine, responds to throttle and mixture control settings from the cockpit and supplies the proper amount of fuel to the fuel manifold. The manifold divides the fuel and sends it to an injector in each cylinder. A fuel pressure gauge is placed between the fuel control unit outlet and the manifold to monitor the injector-applied pressure that indicates engine power.

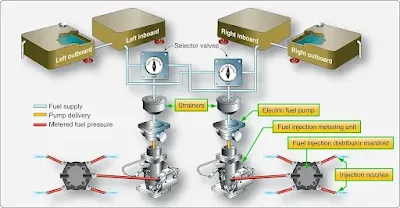

High-Wing Twin

A simplified system on a high-wing, twin-engine aircraft that combines gravity feed with an electric fuel pump is illustrated in Figure 6. Directly downstream of the selector valves are the fuel strainers and then an electric fuel pump for each engine. This pump draws fuel from the selected tank and sends it under pressure to the inlet side of the fuel injection metering unit. The metering unit for each engine provides the proper flow of fuel to the distribution manifold which feeds the injectors. |

| Figure 6. A simple high-wing fuel injection fuel system for a light twin reciprocating-engine aircraft |

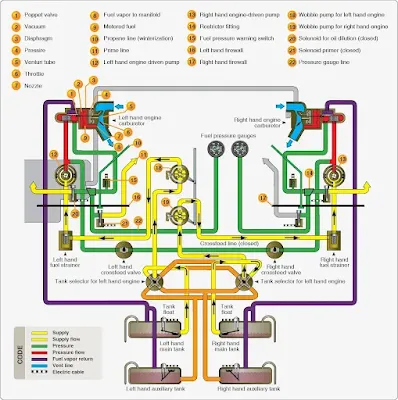

Large Reciprocating Engine Aircraft Fuel Systems

Large, multiengine transport aircraft powered by reciprocating radial engines are no longer produced. However, many are still in operation. They are mostly carbureted and share many features with the light aircraft systems previously discussed.Figure 7 shows the fuel system of a DC-3. A selector valve for each engine allows an engine-driven pump to pull fuel from the main tank or an auxiliary tank. The fuel passes through a strainer before reaching the pump where it is delivered to the engine. The outlet of the pump can feed either engine through the use of a crossfeed line with valves controlled in the cockpit. A hand-operated wobble pump located upstream of the strainer is used to prime the system for starting. Fuel vapor lines run from the pressure carburetor to the vent space in the main and auxilliary tanks. Fuel pressure gauges are tapped off of the carburetor for power indication.

|

| Figure 7. DC-3 fuel system |

The hand-operated wobble pumps were replaced by electric pumps on later model aircraft. A fuel pressure warning light tapped in downstream of the engine-driven fuel pump alerts the crew should fuel pressure decline.

Not all large, old aircraft have this fuel system. This is merely an example. Others aircraft share similar features and possess unique features of their own. The same is true for small reciprocating-engine aircraft. There are many systems that share features with those described above, but they also differ in some ways. Always consult the manufacturer’s data when working on aircraft fuel systems and follow all instructions for service and repair. The fuel system of an aircraft provides the life blood for engine operation and must be maintained with the highest discretion.

Jet Transport Aircraft Fuel Systems

Fuel systems on large transport category jet aircraft are complex with some features and components not found in reciprocating-engine aircraft fuel systems. They typically contain more redundancy and facilitate numerous options from which the crew can choose while managing the aircraft’s fuel load. Features like an onboard APU, single point pressure refueling, and fuel jettison systems, which are not needed on smaller aircraft, add to the complexity of an airliner fuel system.Jet transport fuel systems can be regarded as a handful of fuel subsystems as follows:

- Storage

- Vent

- Distribution

- Feed

- Indicating

Most transport category aircraft fuel systems are very much alike. Integral fuel tanks are the norm with much of each wing’s structure sealed to enable its use as a fuel tank. Center wing section or fuselage tanks are also common. These may be sealed structure or bladder type. Jet transport aircraft carry tens of thousands of pounds of fuel on board. Figure 8 shows a diagram of a Boeing 777 fuel tank configuration with tank capacities.

|

| Figure 8. Boeing 777 fuel tank locations and capacities |

Note that there are optional fuel storage configurations available on the same model airliner. For example, airlines expecting to use an aircraft on transoceanic flights may order the aircraft with long-range auxiliary tanks. These additional tanks, usually located in the fuselage section of the aircraft, can alter fuel management logistics in addition to complicating the fuel system.

In addition to main and auxiliary fuel tanks, surge tanks may also be found on jet transports. These normally empty tanks located in the wing structure outboard of the main wing tanks are used for fuel overflow. A check valve allows the one-way drainage of fuel back into the main tanks. Surge tanks are also use for fuel system venting.

Transport category fuel systems require venting similar to reciprocating engine aircraft fuel systems. A series of vent tubing and channels exists that connects all tanks to vent space in the surge tanks (if present) or vent overboard. Venting must be configured to ensure the fuel is vented regardless of the attitude of the aircraft or the quantity of fuel on board. This sometimes requires the installation of various check valves, float valves, and multiple vent locations in the same tank. Figure 9 shows the fuel vent system of a Boeing 737.

|

| Figure 9. A fuel vent system with associated float and check valves that stop fuel and keep the tanks vented regardless of the aircraft attitude |

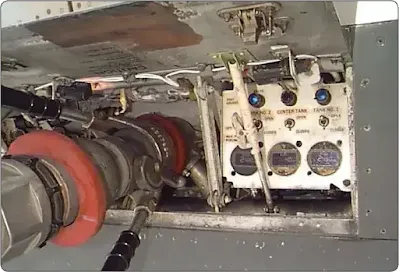

A transport category aircraft fuel distribution subsystem consists of the pressure fueling components, defueling components, transfer system, and fuel jettison or dump system. Single-point pressure fueling at a fueling station accessible by ramp refueling trucks allows all aircraft fuel tanks to be filled with one connection of the fuel hose. Leading and trailing edge wing locations are common for these stations. Figure 10 shows an airliner fueling station with the fueling rig attached.

|

| Figure 10. A central pressure refueling station on a transport category aircraft allows all fuel tanks to be filled from one position |

To fuel with pressure refueling, a hose nozzle is attached at the fueling station and valves to the tanks required to be filled are opened. These valves are called fueling valves or refueling valves depending upon the manufacturer’s preference. Various automatic shutoff systems have been designed to close tank fueling valves before the tanks overfill or are damaged. Gauges on the refueling panel allow refueling personnel to monitor progress.

Occasionally, defueling the aircraft is required for an inspection or repair. The same fueling station is used, and the hose from the fuel truck is connected to same receptacle used to fuel the aircraft. To allow fuel to exit the aircraft, a defueling valve is opened. Fuel can either be pumped out of the aircraft using the boost pumps located in the tanks that need to be emptied, or the pump in the refueling truck can be used to draw the fuel out of the tanks. Control over the operation is maintained by positioning various shutoff and crossfeed valves, as well as the defuel valve so that fuel travels from the tank to the fueling station and into the truck.

The fuel transfer system is a series of plumbing and valves that permits movement of fuel from one tank to another on board the aircraft. In-tank fuel boost pumps move the fuel into a manifold and, by opening the fuel valve (or refueling valve) for the desired tank, the fuel is transferred. Not all jet transports have such fuel transfer capability. Through the use of a fuel feed manifold and crossfeed valves, some aircraft simply allow engines to be run off fuel from any tank as a means for managing fuel location.

Figure 11 shows the fuel system diagram for a DC-10. Dedicated transfer boost pumps move fuel into a transfer manifold. Opening the fuel valve on one of the tanks transfers the fuel into that tank. The transfer manifold and boost pumps are also used to jettison fuel overboard by opening the proper dump valves with a transfer boost pump(s) operating. Additionally, the transfer system can function to supply the engines if the normal engine fuel feed malfunctions.

The fuel feed subsystem is sometimes considered part of the fuel distribution system. It is the heart of the fuel system since it delivers fuel to the engines. Jet transport aircraft supply fuel to the engines via in-tank fuel boost pumps, usually two per tank. They pump fuel under pressure through a shutoff valve for each engine. A manifold or connecting tubing typically allows any tank to supply any engine through the use of crossfeed valves. Boost pump bypasses allow fuel flow should a pump fail. Note that the engines are designed to be able to run without any fuel boost pumps operating. But, each engine’s shutoff valve must be open to allow flow to the engines from the tanks.

Most jet transport fuel feed systems, or the engine fuel systems, have some means for heating the fuel usually through an exchange with hot air or hot oil taken from the engine. Figure 12 shows the fuel cooled oil cooler (FCOC) on a Rolls Royce RB21 1 engine, which not only heats the fuel but also cools the engine oil.

Fuel indicating systems on jet transport aircraft monitor a variety of parameters, some not normally found on general aviation aircraft. Business jet aircraft share many of these features. True fuel flow indicators for each engine are used as the primary means for monitoring fuel delivery to the engines. A fuel temperature gauge is common as are fuel filter bypass warning lights. The temperature sensor is usually located in a main fuel tank. The indicator is located on the instrument panel or is displayed on a multifunction display (MFD). These allow the crew to monitor the fuel temperature during high altitude flight in extremely frigid conditions. The fuel filters have bypasses that permit fuel flow around the filters if clogged. Indicator light(s) illuminate in the cockpit when this occurs.

Low fuel pressure warning lights are also common on jet transport aircraft. The sensors for these are located in the boost pump outlet line. They give an indication of possible boost pump failure.

Fuel quantity gauges are important features on all aircraft. Indications exist for all tanks on a transport category aircraft. Often, these use a capacitance type fuel quantity indication system and a fuel totalizer as is discussed in Fuel System Indicators section.

The location of fuel instrumentation varies depending on the type of cockpit displays utilized on the aircraft.

Helicopter Fuel Systems

Helicopter fuel systems vary. They can be simple or complex depending on the aircraft. Always consult the manufacturer’s manuals for fuel system description, operation, and maintenance instructions.Typically, a helicopter has only one or two fuel tanks located near the center of gravity (CG) of the aircraft, which is near the main rotor mast. Thus, the tank, or tanks, are usually located in or near the aft fuselage. Some helicopter fuel tanks are mounted above the engine allowing for gravity fuel feed. Others use fuel pumps and pressure feed systems.

Fundamentally, helicopter fuel systems differ little from those on fixed-wing aircraft. Gravity-feed systems have vented fuel tanks with an outlet strainer and shutoff valve. Fuel flows from the tank through a main filter to the carburetor. [Figure 13]

|

| Figure 13. A simple, gravity-feed fuel system on a Robinson helicopter |

A slightly more complex system for a light turbine-powered helicopter is shown in Figure 14. Two in-tank electric boost pumps send fuel through a shutoff valve rather than a selector valve, since there is only one fuel tank. It flows through an airframe filter to an engine filter and then to the engine-driven fuel pump. The fuel tank is vented and contains an electrically operated sump drain valve. A pressure gauge is used to monitor boost pump output pressure and differential pressure switches warn of fuel filter restrictions. Fuel quantity is derived through the use of two in-tank fuel probes with transmitters.

|

| Figure 14. A pressure-feed fuel system on a light turbine-powered helicopter |

Larger, heavy, multiengine transport helicopters have complex fuel systems similar to jet transport fixed-wing aircraft. They may feature multiple fuel tanks, crossfeed systems, and pressure refueling.

|

| Watch on YouTube |

RELATED POSTS