Powerplant

The two most common types of engines used in helicopters are the reciprocating engine and the turbine engine. Reciprocating engines, also called piston engines, are generally used in smaller helicopters. Most training helicopters use reciprocating engines because they are relatively simple and inexpensive to operate. Turbine engines are more powerful and are used in a wide variety of helicopters. They produce a tremendous amount of power for their size but are generally more expensive to operate.Reciprocating Engine

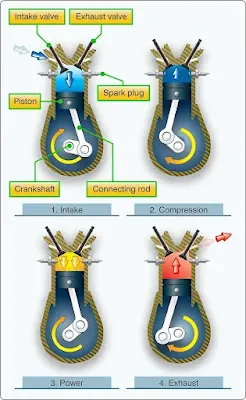

The reciprocating engine consists of a series of pistons connected to a rotating crankshaft. As the pistons move up and down, the crankshaft rotates. The reciprocating engine gets its name from the back-and-forth movement of its internal parts. The four-stroke engine is the most common type, and refers to the four different cycles the engine undergoes to produce power. [Figure 1] |

| Figure 1. The arrows indicate the direction of motion of the crankshaft and piston during the four-stroke cycle |

When the piston moves away from the cylinder head on the intake stroke, the intake valve opens and a mixture of fuel and air is drawn into the combustion chamber. As the cylinder moves back toward the cylinder head, the intake valve closes, and the fuel/air mixture is compressed. When compression is nearly complete, the spark plugs fire and the compressed mixture is ignited to begin the power stroke.

The rapidly expanding gases from the controlled burning of the fuel/air mixture drive the piston away from the cylinder head, thus providing power to rotate the crankshaft. The piston then moves back toward the cylinder head on the exhaust stroke where the burned gases are expelled through the opened exhaust valve. Even when the engine is operated at a fairly low speed, the four-stroke cycle takes place several hundred times each minute. In a four-cylinder engine, each cylinder operates on a different stroke. Continuous rotation of a crankshaft is maintained by the precise timing of the power strokes in each cylinder.

The rapidly expanding gases from the controlled burning of the fuel/air mixture drive the piston away from the cylinder head, thus providing power to rotate the crankshaft. The piston then moves back toward the cylinder head on the exhaust stroke where the burned gases are expelled through the opened exhaust valve. Even when the engine is operated at a fairly low speed, the four-stroke cycle takes place several hundred times each minute. In a four-cylinder engine, each cylinder operates on a different stroke. Continuous rotation of a crankshaft is maintained by the precise timing of the power strokes in each cylinder.