There may be other structures visible on the

wings of an aircraft that contribute to performance. Winglets, vortex generators, stall fences, and gap seals are all common wing features. Introductory descriptions of each are given in the following paragraphs.

A winglet is an obvious vertical upturn of the wing’s tip resembling a vertical stabilizer. It is an aerodynamic device designed to reduce the drag created by wing tip vortices in flight. Usually made from aluminum or composite materials, winglets can be designed to optimize performance at a desired speed. [Figure 1]

|

| Figure 1. A winglet reduces aerodynamic drag caused by air spilling off of the wing tip |

Vortex generators are small airfoil sections usually attached to the upper surface of a wing. [Figure 2] They are designed to promote positive laminar airflow over the wing and control surfaces. Usually made of aluminum and installed in a spanwise line or lines, the vortices created by these devices swirl downward assisting maintenance of the boundary layer of air flowing over the wing. They can also be found on the fuselage and empennage. Figure 3 shows the unique vortex generators on a Symphony SA-160 wing.

|

| Figure 2. Vortex generators |

|

| Figure 3. The Symphony SA-160 has two unique vortex generators on its wing to ensure aileron effectiveness through the stall |

A chordwise barrier on the upper surface of the wing, called a stall fence, is used to halt the spanwise flow of air. During low speed flight, this can maintain proper chordwise airflow reducing the tendency for the wing to stall. Usually made of aluminum, the fence is a fixed structure most common on swept wings, which have a natural spanwise tending boundary air flow. [Figure 4]

|

| Figure 4. A stall fence aids in maintaining chordwise airflow over the wing |

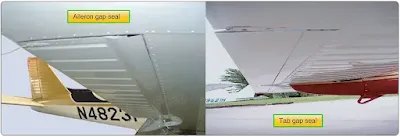

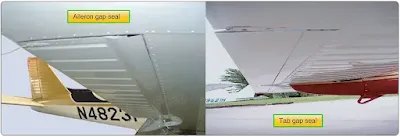

Often, a gap can exist between the stationary trailing edge of a wing or stabilizer and the movable control surface(s). At high angles of attack, high pressure air from the lower wing surface can be disrupted at this gap. The result can be turbulent airflow, which increases drag. There is also a tendency for some lower wing boundary air to enter the gap and disrupt the upper wing surface airflow, which in turn reduces lift and control surface responsiveness. The use of gap seals is common to promote smooth airflow in these gap areas. Gap seals can be made of a wide variety of materials ranging from aluminum and impregnated fabric to foam and plastic. Figure 5 shows some gap seals installed on various aircraft.

|

| Figure 5. Gap seals promote the smooth flow of air over gaps between fixed and movable surface |

RELATED POSTS