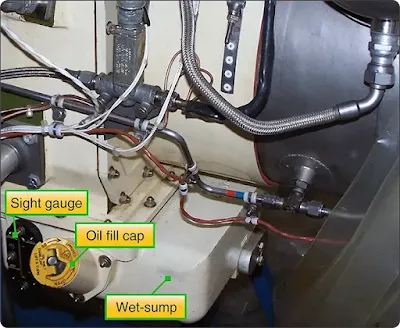

In some engines, the lubrication system is the wet-sump type. There are relatively few engines using a wet-sump type of oil system. A schematic diagram of a wet-sump oil system is shown in Figure.

RELATED POSTS

|

| Typical turbine wet sump system |

The components of a wet-sump system are similar to those of a dry-sump system. The major difference between the two systems is the location of the oil reservoir. The reservoir for the wet-sump oil system may be the accessory gear case or it may be a sump mounted on the bottom of the accessory case. Regardless of configuration, reservoirs for wet-sump systems are an integral part of the engine and contain the bulk of the engine oil supply.

Included in the wet-sump reservoir are the following components:

- A sight gauge indicates the oil level in the sump.

- A vent or breather equalizes pressure within the accessory casing.

- A magnetic drain plug may be provided to drain the oil and also to trap any ferrous metal particles in the oil. This plug should always be examined closely during inspections. The presence of metal particles may indicate gear or bearing failure.

- Provision may also be made for a temperature bulb and an oil pressure fitting.

This system is typical of all engines using a wet-sump lubrication system. The bearing and drive gears in the accessory drive casing are lubricated by a splash system. The oil for the remaining points of lubrication leaves the pump under pressure and passes through a filter to jet nozzles that direct the oil into the rotor bearings and couplings. The oil is returned to the reservoir (sump) by gravity. Oil from the compressor bearing and the accessories drive coupling shaft drains directly into the reservoir. Turbine oil drains into a sump where the oil was originally pumped.